What is 5182 aluminum sheet alloy?

5182 aluminum sheet’s primary alloying element is magnesium, it is a wrought alloy that has good corrosion resistance.

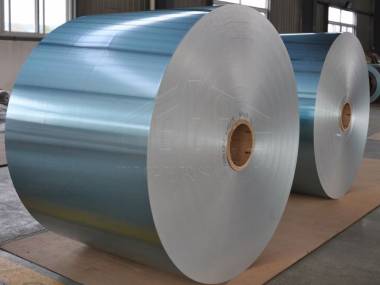

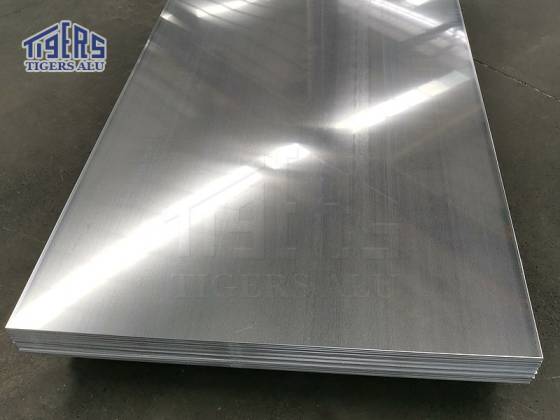

5182 aluminum sheet

5182 aluminum alloy belongs to Al-Mg alloy, which is also a 5 series rustproof aluminum, and its main component Mg content is up to 4%~5%. Therefore, 5182 aluminum sheet has strong corrosion resistance. In addition, a small amount of Si is added to improve its weldability, which can adapt to gas welding, argon arc welding, spot welding, and other welding methods.

5182 aluminum sheet/coil is widely used in the packaging industry and construction industry, it has been recognized as a very promising alloy with good weldability, corrosion resistance, moderate strength, and cold processing properties.

Besides, 5182 aluminum sheet/plate/coil also has excellent processability, which makes it widely used in automobiles, shipbuilding, construction, and industry. 5182 H48 aluminum can be used as the material for can end. (bottle body material is 3104 H19 aluminum).

3104 aluminum can

5182 alloy is the Aluminum Association (AA) designation for this material. By European standards, it will be given as EN AW-5182. A95182 is the UNS number. Additionally, the EN chemical designation is AlMg4,5Mn0,4.

5182 aluminum alloy chemical composition

| Elements | Si | Fe | Cu | Mn | Mg | Zn | Others | Al |

| Content | ≤0.20 | 0~0.35 | 0.15 | 0.2~0.5 | 4.0~5.0 | ≤0.25 | 0.05 | Remain |

| Aluminium/ Temper | Specified thickness | Tensile strength (MPa) |

Yield strength (MPa) |

Elongation (%) |

| H111-H38 | 0.2-50mm | 173-269 | 66-211 | 4-19 |

Heat Treatment Process of 5182 Aluminium

- Homogenization annealing: heating 460 ~ 475 ° C; holding 12 ~ 14h; air cooling.

- Rapid annealing: heating 350 ~ 410 ° C; holding time 30 ~ 120min; empty or water-cooled.

- High-temperature annealing: heating 350 ~ 420 ° C; when the finished product thickness ≥ 6mm or <6mm, the holding time is 10 ~ 30min or 2 ~ 10min; air cooling.

- Low temperature annealing: heating 250 ~ 300 ° C; holding time is 1 ~ 2h, air cooling.

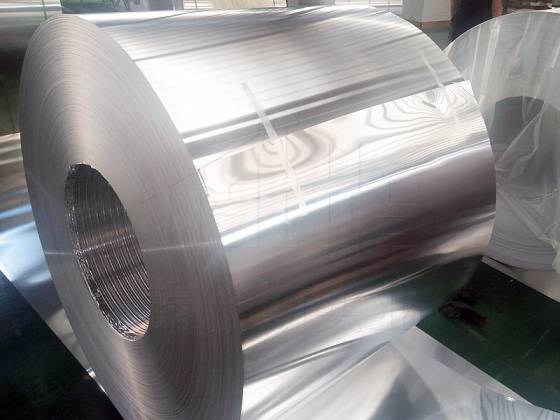

5182 aluminum coil

The Features of 5182 Aluminum Alloy

- Strong Corrosion Resistance. Similarly, the surface of 5182 aluminum sheet can form a dense oxide film, which plays a good role in rust prevention, acid resistance, and alkali resistance.

- Strong Weather Resistance. The 5182 aluminum sheet used for the automobile body or building exterior wall is sprayed with special paint or PVDF fluorocarbon paint. The service life is up to 25 years and the color will not fade.

- High Plasticity. 5182 aluminum sheet/ plate has good forming and processing performance, which can be well adapted to milling, boring, planning, and other mechanical processing at the maximum speed that can be achieved by most machine tools.

- Mechanical Properties. 5182 aluminum sheet tensile strength σb(MPa)≥175, conditional yield strength σ0.2(Mpa)≥80, elongation δ5(%)≥15.

- 5182 alloy also has high fatigue resistance: which can not be heat-treated and hardened in semi-cold. Its plasticity is still good and is low during cold work hardening, the polishing is possible. But the machinability is poor.

5182-h19 aluminum sheet / coil

5182-h19 aluminum sheet/coil is the perfect material commonly used for can lids. H19 tempered 5182 aluminum alloy has the characteristics of light weight, heat resistance, odorless and non-toxic, good printing effect, high recovery rate, etc. It is widely used in beer and beverage packaging cans.

Technical Parameters of 5182 Aluminum

| Aluminium alloy | 5182 |

| Material temper | F, O, H12, H16, H19, H28, H32, H34, H36, H38, H111, H112, H114, H116, H321 |

| Thickness (mm) | 0.1-500 |

| Width (mm) | 20-2650 |

| Length (mm) | Customized |

| Delivery Terms | FOB, CFR, CIF |

Applications of 5182 Aluminium Sheet /Coil

The 5182 aluminum sheet can be used for the car door, Hood, Shipside/bottom plate, deck, refrigeration equipment, tank car, oil tanks, various liquid containers, and other low-load parts made by deep drawing. etc.

aluminum pressure tank

As a professional manufacturer of 5182 aluminum sheet, Tigers aluminum can provide 5182 aluminum sheets with reliable quality, competitive prices, and prompt delivery. Common specifications are in stock. Special sizes can be customized according to clclient’sequests.

5182 aluminum plate is the latest high-magnesium alloy tanker which was born for the European road dangerous goods transportation agreement in recent years. Its tensile strength and elongation value are relatively high. In addition, the mechanical properties of the weld can reach the minimum value specified for the base metal.

Aluminum plate production

Aluminum alloy tanks have good compatibility with most chemical media and foods such as acetone, benzene, gasoline, diesel, kerosene, glacial acetic acid, etc., and the transportation range is relatively wide. Its maintenance cost is very low and will not rust when scratched. It has a typical service life of about 15-20 years.

5182 aluminum VS other alloy aluminum

5082 aluminum vs 5083 aluminum and 5052 aluminum

Its tensile strength is slightly better than 5052 and 5083 aluminum alloys, and its yield strength is also better than 5052 and 5083 alloys. Because the alloy contains a trace element Si, it has excellent welding performance, which can be used for gas welding, electric welding, seam welding, and argon arc welding.

5mm 5052 aluminum plate

5182 aluminum sheet vs 5A02 aluminum

5182 aluminum plate is Al-Mg rust-proof aluminum, performance of the 5182 aluminum plate is similar to 5A02, but because the magnesium content is slightly higher than 5A02, and a small amount of silicon is added, the weldability is better than 5A02, and the 5182 aluminum plate is gas-welded and argon-arc. The welding performance of welding, spot welding, and seam welding is very good, and there is no big difference in other performance.

How does this grade compare to the 5052 aluminum series?

These two 5xxx series alloys share the same base composition. The main difference is that 5182 has a greater percentage of magnesium than 5052, whereas 5052 has more aluminum. More magnesium directly results in mechanical differences related to strength. For example, when you compare the ultimate tensile strength, depending on the temper 5052 has a range of 27 MPa to 41 MPa while 5182 exhibits a range of 41 MPa to 61 MPa.

Video

More info:

Shipping & Packaging

To ensure that the surface of the 5182 aluminum sheet/plate is intact without scratches, we will clamp paper and cover film on the 5182 aluminum sheet/plate.

packed aluminum sheet

The plastic or kraft paper package is used for moisture-proof and rainproof to ensure that the 5182 aluminum plate is clean and free from dirt during transportation.

We add wooden support and reinforce it with a steel belt to avoid collision during transportation and ensure the shape of the 5182 aluminum plate is unchanged;

Export products are all packaged in wooden cases and brackets marked with fumigation.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.