Aluminium alloy 5083 contains 5.2% magnesium, 0.1% manganese and 0.1% chromium. In the tempered condition, it is strong, and retains good formability due to excellent ductility.

| Grade | Max (%) | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each |

Others: Total |

Al: Min. | |

| 5083 alloy | 0.40 | 0.40 | 0.10 | 0.4~1.0 | 4.0~4.9 | 0.05~0.25 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

5083 H321 aluminum sheet plate

This is an excellent marine environment corrosion resistant aluminum alloy, It is primarily an alloy used for its corrosion resistant properties as it is especially good on inter granular corrosion resistance.

Also, the tensile and yield strength is higher than 5086 alloy, so often these properties too are used by designers for their aluminum vessels. This alloy also has good welding capabilities for fabricating vessels.

Physical properties of 5083 aluminum sheet

The 5000 series grades of aluminium are non heat-treatable alloys. 5083 alloy aluminium metal sheet has the highest strength of the non-heat treatable alloys but is not recommended for use in temperatures in excess of 65°C.

| Property | Metric | Imperial |

|---|---|---|

| Density | 2650 kg/m³ | 0.0961 lb/in³ |

| Melting Point | 591-638°C | 1095-1180°F |

Aluminium 5083 has higher Tensile and Yield strengths than Alloy 5086 but less than 5456. it is a strong magnesium-manganese-chromium-aluminium alloy. It can be hardened by cold work.

5083 aluminum sheet is a medium strength, composed mainly of aluminum, magnesium and manganese and standard specifications include AMS 4057, AMS 4058, ASTM B210 and more.

5083 Aluminum Alloy Metal – Supplied in sheet marine grade tempers H116, H321, H323; to spec ASTM B928. Tempers.O, H112, H32; to spec ASTM B209, and extrusion shapes in various tempers and specifications.

| Alloy & Temper |

Spec | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) | Elongation (% in 50mm) minimum for sheet or plate thicknesses shown |

||

| All gauges (Note 2) | 5.0- 12.5mm |

6.31- 80.0mm |

||||

| 5083-O | B209M | 270-345 | 115-200 | – | – | 16 |

| 5083-H32 | B209M | 305-385 | 215 min | – | 12 | – |

| 5083-H116 | B928M | 305 min(1) | 215 min(1) | 10 | – | – |

| 5083-H321 | B928M | 305-385(1) | 215 min(1) | 10 – 12 | – | – |

There are many annealing tempers for 5083 aluminum alloy, and the properties of different states are also different.

Alloy 5083 H321 and H116 aluminum plate are usually used on ship/ boat building.

O, H32, H38 can be used in automobile and other industries.

Properties for H116 and H321 reduced at thickness over 40mm. Tensile strength 285MPa min and yield strength 200MPa min.

Elongations specified for H116 and H321 vary slightly depending on gauge. Measurement gauge length also varies. Refer to ASTM B928M for details.

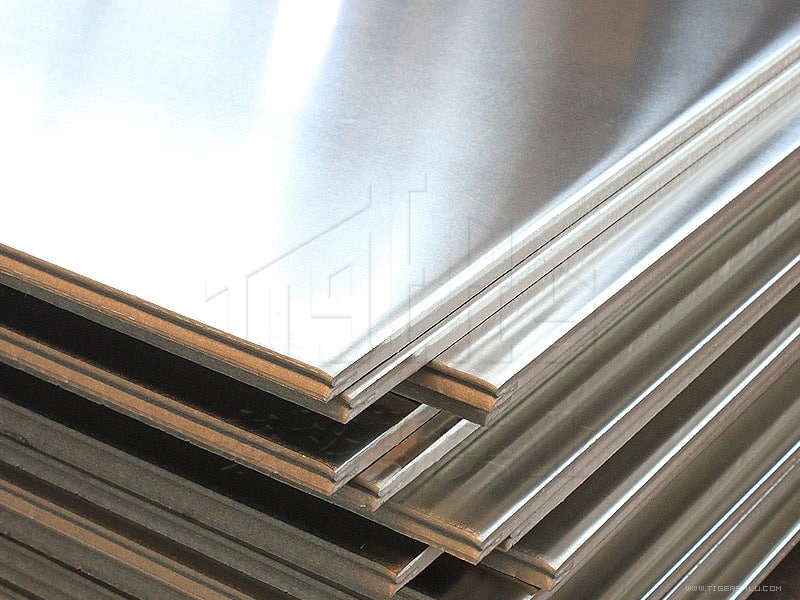

5083 aluminum plate

Properties specified for tempers O and H32 also vary slightly depending on sheet or plate thickness. Specialist tempers F and H112 are also possible in 5083 – refer to ASTM B209M for details.

| Alloy | Density (kg/m3) | Elastic Modulus (GPa) |

Mean Coefficient of Thermal Expansion 20-100℃ (μm/m/℃) |

Thermal Conductivity at 25℃ (W/m.K) |

Electrical Conductivity MS/m at 20℃ |

Electrical Resistivity (nΩ.m) |

|

| Equal Volume | Equal Mass | ||||||

| 5083 | 2660 | 71 | 23.8 | 117 | 17 | 57 | 59 |

| Alloy | Why it might be chosen instead of 5083 |

| 3003 | Brighter appearance required, particularly when considering treadplate. Much lower strength. |

| 5005 | Bright (decorative) anodising finish is required and lower strength is acceptable. |

| 5052 | Required as treadplate and lower strength is acceptable. |

Bending Radii

| Temper | 0.4mm | 0.8mm | 1.6mm | 3.2mm | 4.8mm | 6.0mm | 10mm | 12mm |

| O | – | – | ½ t | 1t | 1t | 1t | 1½t | 1½t |

| H321 | – | – | – | – | 1½t | 1½t | 2t | 2½t |

Recommended minimum bending radius for sheet or plate of thickness given, at 90°to the rolling direction. These values are recommended but are not guaranteed; the minimum possible bend radius will depend on the type of bending equipment and on the tooling and its condition.

References

- ASTM B209M – 10. Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate.

- ASTM B928M – 09. Standard Specification for High Magnesium Aluminum-Alloy Sheet and Plate for Marine Service and Similar Environments.

- Bushfield, H., Marine Aluminum Plate – ASTM Standard Specification B928 And The Events Leading To Its Adoption.

- Aluminum Association – Aluminum Standards and Data – 2009 Metric SI.

- WTIA Technical Note 2 – Successful Welding of Aluminium.

Alloy 5083 aluminum plates have higher strength than 5052 plate and has exceptional thermal conductivity. In the tempered condition, it retains good formability due to excellent ductility, and it is easy to form, stamp and weld.

5083 aluminum mechanical properties

| Property | Metric | Imperial |

|---|---|---|

| Hardness, Brinell | 85 | 85 |

| Hardness, Knoop | 109 | 109 |

| Hardness, Rockwell A | 36.5 | 36.5 |

| Hardness, Rockwell B | 53 | 53 |

| Hardness, Vickers | 96 | 96 |

| Ultimate Tensile Strength | 317 MPa | 46000 psi |

| Tensile Yield Strength | 228 MPa | 33000 psi |

| Elongation at Break | 16% | 16% |

| Modulus of Elasticity | 70.3 GPa | 10200 ksi |

| Compressive Modulus | 71.7 GPa | 10400 ksi |

| Poissonn’s Ratio | 0.33 | 0.33 |

| Fatigue Strength | 159 MPa | 23000 psi |

| Fracture Toughness | 43 MPa-m½ | 39.1 ksi-in½ |

| Machinability | 30% | 30% |

| Shear Modulus | 26.4 GPa | 3830 ksi |

| Shear Strength | 190 MPa | 27600 psi |

It is highly suitable for welding and can be hardened by cold work. Because Alloy 5083 with excellent corrosion resistance, particularly salt water corrosion resistance, it is used in marine applications.

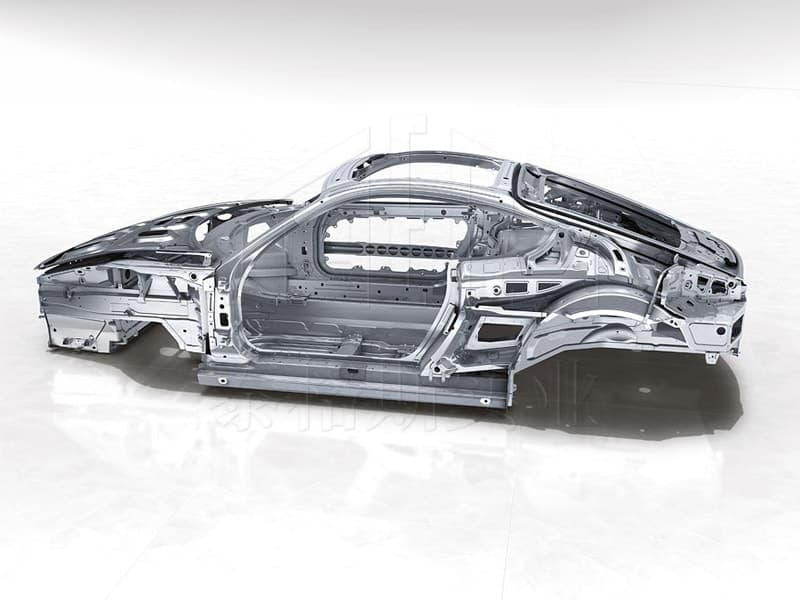

auto shell made of aluminum sheet

Since Alloy 5083 aluminum sheet plate is capable of withstanding extremely low temperatures without brittleness or loss of properties, it is especially suited to the cryogenic market. Alloy 5083 has been used in vehicle armor plate due to its high strength factor.

Aluminium 5083 is known for exceptional performance in extreme environments. Aluminium 5083 is highly resistant to attack by both seawater and industrial chemical environments.

The temper is achieved by the plate being fully annealed and then rolled to the required temper, rather than being heat treated.

| Temper | Tensile Strength | Yield Strength | Elongation |

| KSI | KSI | % | |

| O (annealed) | 42 | 21 | 14 |

|---|---|---|---|

| H112 | 43 | 23 | 10 |

| H116 | 46 | 33 | 10 |

| H321 | 46 | 33 | 10 |

-O, F, H111, H112, H12, H14, H22, H24,

-H32, H34, 38

-T4, T6, T651, T6511

-T6, T651, T6511, T7351

Annealing – O, F

Hot Work- T1, H111, H112

Cold Work – H12, H14, H16, H18, H32, H34, H116, H321

Heat Treatment – T3, T4, T5, T6, T8

Over Aging Treatment – T73, T74, T76, T79

Stress Relieved – T351, T451, T651, T7351, T7451, T7651, T7951, T851

Tigers aluminum stocks thicknesses from .250″ – 2.00″, widths up to 120″ and lengths up to 300″ or can accommodate any customer specific requirements. All material is fully certified to ASTM B209 and ASME SB209.

Applications of 5083 aluminum sheet

- It has the low density and excellent thermal conductivity common to all aluminium alloys. Alloy 5083 is best known as a plate for ship building.The alloy is also produced as extruded seamless tube and other extrusions and as forgings.

- Shipbuilding, Pressure Vessels and General maritime fabricated products.

- require a weldable alloy of high to moderate strength, with good corrosion resistance.

- Commonly used in the manufacture of unfired, welded pressure vessels, marine, auto aircraft cryogenics, drilling rigs, TV towers, transportation equipment, and in missile components, drilling rigs, armour plate.

- Its high corrosion resistance, especially salt water corrosion resistance, makes it an excellent material for marine and processing applications.

- 5083 aluminum sheet performs well in extremely cold environments without becoming brittle and is a popular material for cryogenic equipment. It is easy to form, stamp and weld. 5083 has high resistance to corrosion, and is used in marine applications.

5083 Marine Grade Aluminum metal. The commonly used temper of 5083 aluminum sheet is H116/ H321/ H112, with a thickness of 3-200mm and a width of 1500-2600mm.

It is widely used for ship engine bases, ship decks, ship sides, bottom outer plates, etc., covering the hulls of yachts and cruise ships, etc.

boat made of aluminum sheet

5083 Medium Thickness Aluminum Plate/ Ultra Wide 5083 Aluminum Sheet: Mold, LNG storage tank, flange material, GIS high-voltage switch housing, precision machining, etc.

Other uses for this alloy include transportation applications such as rail, truck, and vehicle bodies, as well as pressure vessels and food processors.

Specification of 5083 aluminum sheet

| Dimension | Range |

| Thickness | 0.5 ~ 6.0mm for sheet,max 600mm |

| Width | 600 ~ 2,200mm |

| Length | 2,000 ~ 10,000mm |

- – Standard Width and Length: 4〃 x 8〃, 4“ x 4“ , 4 in. x 10 in. aluminum sheet, 5 x 10 aluminum sheet, 48‘ x 96’ aluminum sheet, 1219 * 2438mm, 1220mm x 2440mm aluminum sheet, 1000mm x 2000mm aluminum sheet, 1250mm x 2500mm, 1219x2438mm, 1524x3048mm, 1500mm x 3000mm aluminum sheet.

- – Surface Finish: Mill finish (unless otherwise specified), Color Coated, or Stucco Embossed

- – Surface Protection: Paper interleaved, PE/PVC filming (if specified)

- – Minimum Order Quantity: 3MT

5083 aluminum metal sheet vs. 6061 aluminum alloy metal

Aluminum 5083 plate is the representative product of the 5 series. Most of the temper is H321, H116, 5083 was usually used in the shipbuilding industry. 6061 aluminum is the representative product of the 6 series, the temper is generally 6061-T6, 6061-T651 and 6061-T652.

5083 aluminium alloy on wikipedia

https://en.wikipedia.org/wiki/5083_aluminium_alloy

What is the difference in aluminium sheet and aluminum plate?

Comparison of 5083 aluminum and other aluminum alloys

5083 aluminum alloy sheet VS. 6061 aluminum metal sheets

5083 aluminium other product forms:

5083 Aluminum Sheet

5083 Aluminum Plate

5083 Aluminum circle/Disc

5083 Aluminum Billet

5083 Aluminum Ingot

5083 Aluminum Machined Part

packed aluminum sheet

Most of Tigers 5083 aluminum sheet plate and plate stock is available in full size and custom cut lengths.

At Tigers aluminum, we have 10+ years of experience supplying 5083 aluminum forgings, plate, sheet and more to your custom measurements.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.