What alloys can be used to make aluminum can end

What are the available alloys for aluminum can end material?

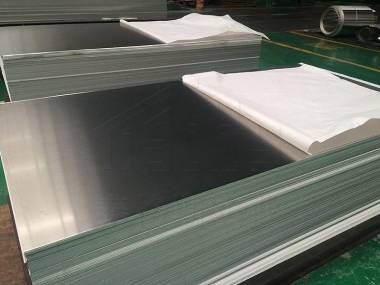

The aluminum alloys 5182 H48 aluminum coil, 5052 H48 aluminum coil, 5042 H48 aluminum coil, 3104 H48 aluminum coil are commonly used in the manufacture of aluminum can end.

aluminum can end

3104 H48, 5052 H48, 5182 H48 and 3004 H48 are all alloys that are tempered to the H48 state and have the following properties in common that make them suitable for aluminum can end.

Common properties of aluminum alloys in H48 condition

Good strength and ductility

These aluminum alloys have good strength and ductility, can be easily formed into can shapes during molding and machining, and can withstand the stresses and pressures of transportation and use.

Good corrosion resistance

These aluminum alloys all have excellent corrosion resistance and can be used in wet and corrosive environments for long periods of time without affecting their performance and appearance.

Recyclability

Aluminum can end are a recyclable packaging material, and can lids made with these aluminum alloys can be recycled and reclaimed to reduce waste and environmental pollution problems.

Cost-effectiveness

These aluminum alloys are relatively low cost compared to other metals and alloys, and therefore can provide cost effectiveness when producing large quantities of aluminum can end.

2 pcs aluminum can end

Suitable material for aluminum can body is 3104 H19 aluminum coil

Characteristics of different alloys

Different types of aluminum alloys differ in some of their properties.

- 3104 H48 alloy is more suitable for stamping and drawing processes.

- 5052 H48 alloy is more suitable for high strength applications.

- 5182 H48 alloy is suitable for high speed forming processes, etc.

Therefore, in the specific production application, you can choose different types of aluminum alloy as the aluminum can end material according to different needs.