What is 5005 aluminum alloy?

Aluminium alloy 5005 contains 0.8% magnesium, and aluminum alloy commonly available in flat rolled coil, 5005 aluminum sheet, and plate from a wide range of producing mills, tigers supports bulkbuy.

It has medium strength, good weldability, and good corrosion resistance in marine atmospheres. Aluminum 5005 alloy metal is a lean aluminum-magnesium alloy with low density and excellent thermal conductivity. Tempers H116 and H321 can be used in fresh and saltwater.

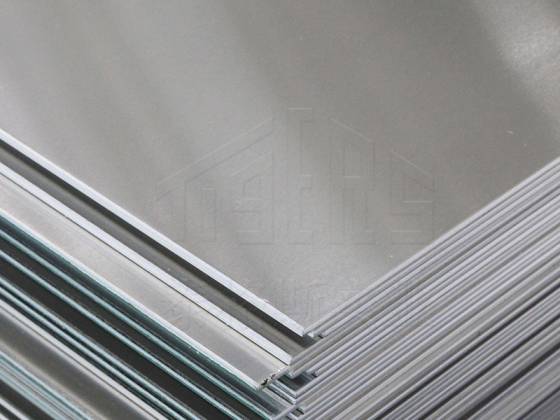

8mm 5005 h32 aluminum sheet plate

5005 has only a very small addition of magnesium so is the least strength of 5000 series of alloys.

The alloy is hardenable to a significant degree by cold working, enabling a series of “H” tempers but again these do not achieve the high strengths of corresponding tempers in other alloys such as 5052 or 5083.

Equivalent name

A5005, 5005a, aa5005, 5005aa, al5005, al5005a, a 5005, aa 5005, jis a5005p, al5005 class, aw5005, en5005 grade etc

5005 aluminium alloy temper

Alloy 5005 aluminum plate sheet is not hardenable by heat treatment. It can be significantly hardened by cold work (eg by cold rolling) and various “H” tempers are produced – most commonly H32 (¼ Hard) and H34 (½ Hard) – as well as the soft annealed Temper O condition.

The alloy spontaneously age-softens at room temperature immediately after cold work but will eventually reach a stable condition;

5005 alloy is the most commonly used grade of aluminium in aluminium sheet and aluminium plate form.

Tigers aluminum is a aluminum 5005 h34 manufacturer and wholesale, we provide h34 aluminum 5005 in flat rolled aluminum coil, sheet and plate.

5mm 5052 aluminum plate

What are the 5000 series alloys?

It is a member of the 5000 series of aluminum-magnesium wrought alloys. others 5000 series aluminum alloy:

5005 Aluminum Sheet

5052 aluminum sheet

5083 Aluminum Sheet

5086 Aluminum Sheet

5182 Aluminum Sheet

5252 Aluminum Sheet

5454 Aluminum Sheet

5754 Aluminum Sheet

5A02 Aluminum Sheet

5A03 Aluminum Sheet

5A05 Aluminum Sheet

5A06 Aluminum Sheet

Almost all aluminum and aluminum alloy varieties are used on ships. Currently used most is the 5XXX series. Marine grade aluminium 5005 is one of them. The aluminum varieties are aluminum thick plate, aluminum plate, aluminum sheet, aluminum strip, aluminum foil, aluminum tube, and so on.

5005 aluminum sheet/plate chemical composition

Chemical Composition conforms to Chinese, American, and European standard specification

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: each other |

Others: Total |

Al: Min. |

| 5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.5~1.1 | 0.1 | 0.25 | – | 0.05 | 0.15 | remainder |

5005 aluminum sheet belongs to 5-series Al-Mg alloy, but the content of the main alloy Mg is less than that of other 5-series alloy sheets, so it has a slightly higher corrosion resistance than the 3-series alloy. Among them, the performance of 5005 aluminum alloy is similar to that of 3 series 3003 aluminum alloy, with moderate strength, good fusion, processing, and formability.

Physical properties of 5005 aluminum sheet

Heat Treatment of Aluminium Alloy 5005

Aluminium 5005 is annealed at 345°C, time at temperature and cooling rate are unimportant. Stress relief is rarely required but can be carried out at about 220°C. If loss of strength is of concern, stress relief tests should be conducted.

Mechanical Property Specification (single values are minima except as noted)

5mm 5005 h32 aluminum plate

| Alloy & Temper |

Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) min |

Elongation (% in 50mm) minimum for sheet or plate thicknesses shown |

||||

| 0.15-0.32mm | 0.33-0.63mm | 0.64-1.20mm | 1.21-6.30mm | 6.31-80.0mm | |||

| 5005-O | 105 – 145 | 35 | 12 | 16 | 19 | 21 | 22 |

| 5005-H32 | 120 – 160 | 85 | – | 3 | 4 | 7 | 10 * |

| 5005-H34 | 140 – 180 | 105 | 2 | 3 | 4 | 5 | 8 * |

| 5005-H36 | 160 – 200 | 125 | 1 | 2 | 3 | 4 * | – |

| 5005-H38 | 180 min | – | 1 | 2 | 3 | 4 * | – |

Tempers H22 and H24 etc may not meet maximum tensile strength and minimum yield strength limits, but if supplied in place of ordered H32 or H34 all limits must be complied with.

* properties for H32 only specified up to 50mm, H34 to 25mm, H36 to 4.0mm, and H38 to 3.2mm thick.

Specialist tempers such as F, H116, H112, and H141 are also possible in 5052 – refer to standards for details.

| Alloy | Density (kg/m3) | Elastic Modulus (GPA) |

Mean Coefficient of Thermal Expansion 20-100°C (mm/m/°C) |

Thermal Conductivity at 25°C (W/m.K) |

Electrical Conductivity MS/m at 20°C |

Electrical Resistivity (nW.m) |

|

| Equal Volume | Equal Mass | ||||||

| 5005 | 2700 | 69 | 23.8 | 201 | 30 | 100 | 33 |

| Alloy | UNS No | ISO | BS | DIN | |

| No | Name | ||||

| 5005 | A95005 | AlMg1 | N41 | 3.3315 | AlMg1 |

These comparisons are approximate only. The list is intended as a comparison of functionally similar materials, not as a schedule of contractual equivalents. If exact equivalents are needed original specifications must be consulted.

| Alloy | Why it might be chosen instead of 5005 |

| 3003 | Brighter appearance required, particularly when considering treadplate. |

| 5052 | Higher strength or treadplate required. Decorative anodizing is not required. |

| 5083 | Higher strength or improved corrosion resistance is required, particularly for ship hull applications. |

Indicative minimum bend radii for 90° cold forming for various thicknesses, t mm

| Temper | 0.4mm | 0.8mm | 1.6mm | 3.2mm | 4.8mm | 6.0mm | 10mm | 12mm |

| O | 0t | 0t | 0t | 0t | ½t | 1t | 1t | 1½t |

| H32 | 0t | 0t | 0t | ½t | 1t | 1t | 1½t | 2t |

| H34 | 0t | 0t | 0t | 1t | 1½t | 1½t | 2t | 2½t |

| H36 | ½t | 1t | 1t | 1½t | 2½t | 3t | 3½t | 4t |

| H38 | 1t | 1½t | 2t | 2½t | 3½t | 4½t | 5½t | 6½t |

Recommended minimum bending radius for sheet of thickness given, at 90° to the rolling direction.

These values are recommended but are not guaranteed; the minimum possible bend radius will depend on the type of bending equipment and the tooling and its condition.

Welding Aluminium Alloy 5005

It can attain moderate to high strength by cold working and has relatively high welded strength, workability, and corrosion resistance compared to other aluminum alloy families. Aluminum 5005 is readily machinable and can be welded using TIG and MIG methods. Aluminium must be very dry & clean to avoid contamination & porosity of the weld. Filler metals 1100, 4043, or 4047 are used.

Video

Applications of Aluminium Alloy 5005

Due to its many benefits, Aluminum 5005 is in use in a wide variety of applications and industries including:

- Roofing & siding materials

- Chemical & food equipment

- Storage tanks

- Home appliances

- Sheet-metal work

- Electric conductors

- High Strength foil

- HVAC equipment

- Furniture

Marine grade aluminium 5005 is widely used in ship shells. The form of the hull structure can be divided into three types: horizontal skeleton type, vertical skeleton type, and mixed skeleton type. Aluminum alloy small fishing boats, the main end structure of large ships is usually horizontal skeleton structure. The aluminum alloy materials used on the hull are mainly plates, profiles, and wide-width extruded slabs.

5005 Aluminum Sheet for Curtain Wall

5005 aluminum sheet can be used as high-end wide-format curtain wall material, which has the advantage of excellent anodic oxidation effect compared with the commonly used 3003 aluminum sheet for curtain wall. In addition, 5005 aluminum alloy is light, only one fifth of the marble, one third of the glass curtain wall, and can be perfectly combined with the glass and stone curtain wall material, presenting a fashion, trend, unique modern architectural style. It is worth mentioning that, the cost-effective price, as well as the low maintenance cost in the later period, make the architects more favor to the 5005 aluminum sheet!

5005 Aluminum Sheet Other Usages

Besides, 5005 aluminum sheet is also commonly used for building decoration parts, vehicle interior materials, instrument panel, oxidizing materials, cooking utensils, conductors, and other manufacturing.

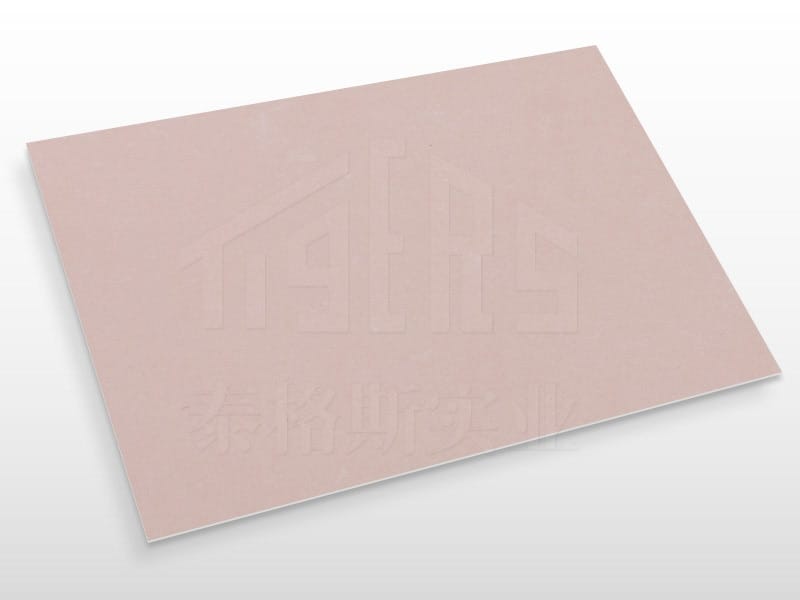

Anodized 5005 aluminum sheet

5005 aluminum alloy metal is formulated for a decorative architectural anodized finish. It allows for a more uniform and attractive anodized finish than other alloys.

5005 Aluminum sheet is often used when the material will be anodized and deployed in an architectural application like flashings, sills, curtain walls, etc. Architects often specify 5005 alloy for anodized aluminum architectural metalwork.

Where anodizing is needed, 5005 is specified for applications similar to 1100 and 3003.

When anodized to improve corrosion resistance, the film on 5005 is clearer than on 3003 and gives better color match with 6063 architectural extrusions.

Light brown anodized 5005 aluminum sheet plate

5005 aluminum sheet VS 5052 aluminum alloy

Many people substitute 5052 for 5005. While 5052 can produce acceptable results, it has more imperfections and is more prone to color variation than 5005 alloy aluminum.

5005 properties and additional information:

General Features

5005 is a non-heat treatable alloy with magnesium content. It can be strengthened (hardened) by cold working. It scores well in weld-ability, formability, and corrosion resistance (especially when anodized).

Forming

5005 has excellent formability, especially in softer tempers. SAF carriers 5005 H34 temper which is slightly harder and is comparable to 5052 H32 for forming.

Welding

5005 alloy is noted for excellent welding characteristics. When 5005 material will be welded and then anodized, SAF recommends a 5356 welding wire for best color uniformity. Weld discoloration can still occur, but it is less severe than other welding alloys.

Machining

5005 machinability is generally fairly poor. Soft 5005 tempers machine worse than harder tempers. 5005 H34 and 5005 H38 can be machined, but with much more difficult than many other aluminum alloys.

| Alloy | Form | Temper | 0.2% Proof Stress, MPa min† | Elongation % min | Tensile Strength, MPa | Yield Strength | Elongation |

| 5005 | Sheet | H12 | 95 | 2-8 | 125 – 165 | 19 | 10 |

| 5005 | Sheet | H14 | 115 | 1-6 | 145 – 185 | 22 | 6 |

| 5005 | Sheet | H16 | 135 | 1-3 | 165 – 205 | 25 | 5 |

| 5005 | Sheet | H18 | – | 1-3 | > 185 | 28 | 4 |

| 5005 | Sheet | H32 | 85 | 3-9 | 115 – 160 | 17 | 11 |

| 5005 | Sheet | H34 | 105 | 2-7 | 135 – 180 | 20 | 8 |

| 5005 | Sheet | H36 | 125 | 1-4 | 160 – 200 | 24 | 6 |

| 5005 | Sheet | H38 | – | 1-4 | > 180 | 27 | 5 |

5005 aluminum alloy on wikipedia

Specification of 5005 aluminum sheet

| Dimension | Range |

| Thickness | 0.5 ~ 6.0mm for sheet, max 500mm |

| Width | 600 ~ 2,650mm |

- – Standard Width and Length: 4〃 x 8〃, 4“ x 4“ , 4 in. x 10 in. aluminum sheet, 5 x 10 aluminum sheet, 48‘ x 96’ aluminum sheet, 1219 * 2438mm, 1220mm x 2440mm aluminum sheet, 1000mm x 2000mm aluminum sheet, 1250mm x 2500mm, 1219 x 2438mm, 1524 x 3048mm, 1500mm x 3000mm aluminum sheet.

- – Surface Finish: Mill finish (unless otherwise specified), Color Coated, or Stucco Embossed

- – Surface Protection: Paper interleaved, PE/PVC filming (if specified)

- – Minimum Order Quantity: 3MT

In addition to the commonly used specifications, Tigers Aluminum can also produce 5005 ultra-wide and ultra-thick aluminum plates with internal stress relief and no deformation during cutting, and the width is 2650mm, the thickness is 500mm.

Standard of 5005 aluminum sheet/plate/coil

- ASTM B209 – This specification covers aluminum and aluminum alloy flat sheet, coiled sheet, and plate in various alloys.

- BS EN 573 – This specification covers aluminium and aluminium alloys – Chemical composition and form of products.

- BS EN 485 – This specification sets out the mechanical properties of wrought aluminium and wrought aluminium alloy sheet, strip, and plate for general engineering applications.

Bulkbuy custom metal 5005 aluminum plate from China manufacturer and supplier, Tigers aluminum ex-factory price multiple specifications wholesale 5005 alloy aluminum plate for sale in stock.

5005 Aluminum Sheet Factory

Tigers aluminum is a factory specializing in the production of 5005 aluminum sheet, wholesale 5005 alloy aluminum in various thicknesses and cut to size, contact our sales manager for a pricelist.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.