What is 3105 aluminum sheet/plate?

3105 aluminum sheet/plate is AL-Mn 3105 metal aluminum alloy, it is essentially a 98% aluminum alloy with minor additions for strength over that of alloy 1100 and 3003. 3105 alloy metal is one of the most widely used anti rust aluminium, It is not hardenable by heat treatment.

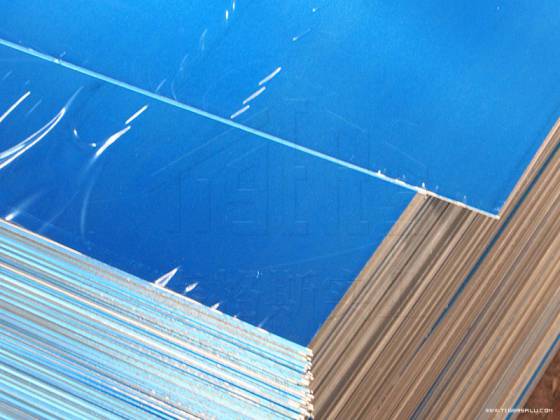

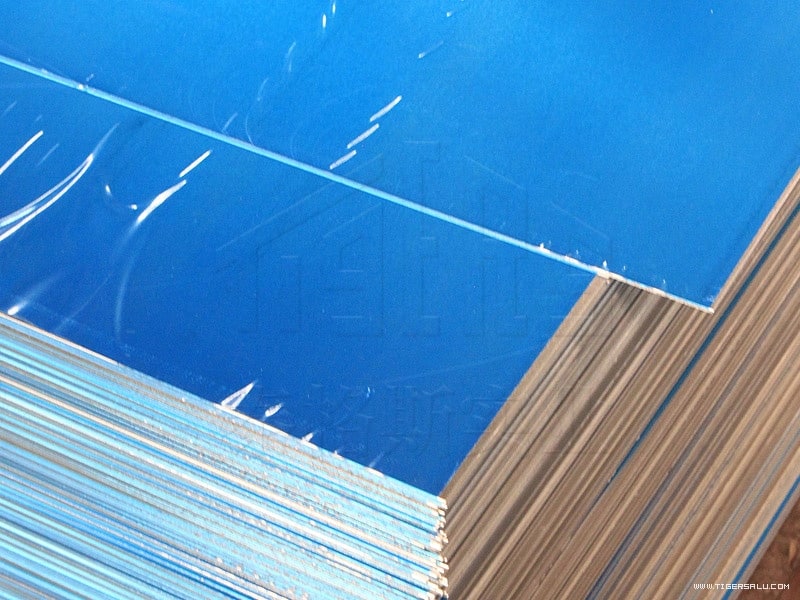

3mm 3105 aluminum sheet

AA 3105 aluminum alloy has good corrosion resistance, good plasticity and processability, and the performance of gas welding and arc welding is good.

Tigersalu manufactures and supplies high quality 3015 aluminum in China. With some sizes available from stock, all at reasonable ex-factory prices. 3015 aluminum can also be purchased as a coil, but in this case it is usually sold by weight.

3105 aluminum alloy metal Chemical Composition (For Reference)

3105 aluminum alloy sheet is a non-heat-treated alloy, which is slightly stronger than the 1 series industrial pure aluminum, and uses cold working to improve mechanical properties.

Chemical Composition conforms to Chinese, American and European standard specification

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each |

Others: Total |

Al: Min. |

| 3105 | 0.60 | 0.70 | 0.30 | 0.3~0.8 | 0.2~0.8 | 0.20 | 0.40 | 0.10 | 0.05 | 0.15 | remainder |

aluminum sheet with blue films

Physical properties of 3105 aluminum sheet

3105 aluminum alloy is not hardenable by heat treatment and it has good corrosion resistance, formability and weldability.

| Item | 3105 Aluminum Data |

| Density, lb/in3 | 0.0983 |

| Modulus of Elasticity, psi | 10.0 x 106 |

| Coefficient of Thermal Expansion, 68-212˚F, /˚F | 12.1 x 10-6 |

| Thermal Conductivity, Btu/ft hr ˚F | 99 |

| Specific Heat, Btu/lb ˚F | 0.214 |

| Electrical Resistivity, Microohm-in | 1.504 |

3105 aluminum sheet with 98% pure aluminum and slight alloy additions for strength. 0.3% of copper is added to 3105 aluminum, so the conductivity turns out to be 41%. For its contents and processing technologies, it is light in weight and it has semi-smooth surface. Besides, it is not hardened by heat treatment.

Mg, Mn and Si are added to 3105 aluminum sheet, thus, it has excellent correction resistance, formability and welding characteristics. Besides, it has average mechinability and it can be increased in harder tempers than in annealed condition.

Other properties for 3105 aluminum alloy metal

| Principal Design Features | This is an essentially 98% pure aluminum alloy with minor additions for strength. It is not hardenable by heat treatment. Corrosion resistance, formability and welding characteristics are excellent. |

| Applications | Commonly used in the manufacture of residential siding, mobile homes, and rain carrying goods. Is commonly used in sheet metal work. |

| Machinability | Machinability of AL 3105 is fair. Oil lubricants should be used for all machining operations. Machinability of the alloy when in the harder (H) tempers is improved over machining in the annealed (O) condition. |

| Forming | The forming characteristics of the alloy are very good by all conventional processes regardless of temper. Bend radii should be in the one thickness to 2 t range for annealed, H12, H14 and H16 tempers. The H18 temper requires bend radii of 2 to 7 t, depending upon thickness of the material. |

| Welding | Weldability of this alloy is excellent by all commercial techniques. Arc welding is preferred for the best results. |

| Heat Treatment | This alloy does not respond to heat treatment except for annealing during cold working. |

| Forging | Forging, if required, may be done in the range of 950 to 700 F. |

| Hot Working | Hot working may be accomplished at 700 to 400 F. |

| Cold Working | The cold working characteristics of AL 3105 are very good, even in the harder cold worked tempers. Bend radii for sheet up to 1/16″ thick vary from 1/2 to one t for all tempers. |

| Annealing | Annealing from a cold worked condition may be accomplished at 650 F followed by air cooling. |

| Aging | Not applicable to this alloy. |

| Tempering | Not applicable. |

| Hardening | Hardens to the H12, 14, 16, 18 or 25 tempers only by cold working. |

| Other Physical Props | Electrical conductivity 41% of copper. |

| Other Mechanical Props | Typical shear strength values are: H14 15 ksi and H16 17 ksi. |

3105 aluminum coil sheet has high plasticity in the annealing state, in the semi cold hardened, the plasticity is still better, it has low plasticity, good weld-ability and poor cutting properties in cold hardening state.

1100 h14 aluminum sheet

The formability of 3105 aluminum sheet is amazing. No matter what type of temper, its forming characteristics are very good in all conventional processes.

3105 aluminum sheet mechanical properties

| Material | Temper | Tensile Strength (N/mm²) | Yield Strength (N/mm²) | Elongation on 50mm | |||

| 0.5 mm | 0.8mm | 1.3mm | 2.6mm | ||||

| 3105 | 0 | 110-155 | – | 16 | 18 | 20 | 20 |

| 3105 | H12 | 130-175 | 115 | 2 | 3 | 4 | 5 |

| 3105 | H14 | 160-205 | 145 | 2 | 2 | 3 | 4 |

| 3105 | H16 | 185-230 | 170 | 1 | 1 | 2 | 3 |

| 3105 | H18 | 215 min | 190 | 1 | 1 | 1 | 2 |

| Alloy Temper |

Specified thickness |

Tensile strength |

Yield strength |

Elongation |

| (inches) | (KSI) | (KSI) | (%) | |

| 3105 (annealed) |

0.013-0.019 | 96-145 | Min34 | 16 |

| 0.020—0.031 | 18 | |||

| 0.032-0.080 | 20 | |||

| 3105-H12 | 0.017-0.019 | 131-179 | Min103 | 1 |

| 0.020-0.031 | 1 | |||

| 0.032-0.050 | 2 | |||

| 0.051-0.080 | 3 | |||

| 3105-H14 | 0.013-0.019 | 152-200 | Min124 | 1 |

| 0.020-0.031 | 1 | |||

| 0.032-0.050 | 2 | |||

| 0.051-0.080 | 2 | |||

| 3105-H16 | 0.013-0.031 | 172-221 | Min145 | 1 |

| 0.032-0.050 | 2 | |||

| 0.051-0.080 | 2 | |||

| 3105-H18 | 0.013-0.031 | Min193 | Min165 | 1 |

| 0.032-0.050 | 1 | |||

| 0.051-0.080 | 2 | |||

| 3105-H25 | 0.013-0.019 | Min15 | Min131 | 2 |

| 0.020-0.031 | 3 | |||

| 0.032-0.050 | 4 | |||

| 0.051-0.080 | 6 |

Advantages of 3105 aluminum metal:

The forming characteristics of 3105 aluminum sheet are pretty good . 3105 aluminum sheet does not respond to heat treatment except for annealing during cold working. The cold working characteristics are very good, even in the harder cold working tempers. For all the features above, 3105 aluminum sheet has a vast application in many field.

- Deep Drawability. The deep drawing performance of 3105 aluminum sheet in O temper better than that of H26 temper, and the deep drawing performance of 3105 aluminum alloy sheet before low temperature treatment is better than that of 24h.

- Plasticity. 3105 aluminum sheet has high plasticity in the annealed state, and its plasticity is good when it is semi-cold-work hardened, and it is low when it is cold-work hardened.

- Solderability. It is worth mentioning that the excellent weldability of 3105 aluminum sheet is applicable to all existing welding technologies, of which arc welding is the best method.

- Other Characteristics. Good corrosion resistance, good anodic oxidation, poor machinability, etc.

Usages of 3004 Aluminum Material Sheet

3105 aluminum sheet is used in general sheet metal works requiring greater strength than is provided by 1000 series aluminum alloys.

Commonly used in the manufacture of residential siding, mobile homes, sign making, and rain carrying goods. commonly used in sheet metal work. Commonly used for coating with lacquer for curtain wall, outside of construction.

Alloy 3105 is widely used for residential siding, mobile homes, goods carriers, truck/trailer roofing, sheet-metal work.

3105 aluminum alloy sheet is a ideal choice of cap material, lamp holder, shutters, rain gear, and sheet metal processing parts. etc. In addition, 3105 aluminum sheet is used for residential wall panels, and mobile house walls also play an important role.

Tiger is also a 3105 prepainted aluminum coil china factory, we use environmentally friendly PVDF paint and advanced CNC coating equipment to make the surface of 3105 aluminum coil and sheet more beautiful

automobile made of aluminum sheet

Specification of 3105 aluminum sheet

| Alloy | Temper | Thickness (mm) |

Width (mm) |

Length (mm) |

| 3105 aluminum sheet | F, H112, O, H111, H12, H22, H32, H14, H24, H34, H16, H26, H18, H19, H28, H38 | 0.2-500mm | 600-2650mm | 500-16000 |

The common product of 3105 aluminum alloy are 3105 aluminum sheet plate and 3105 aluminum foil and 3105 aluminum strip.

- – Standard Width and Length: 4〃 x 8〃, 4“ x 4“ , 4 in. x 10 in. aluminum sheet, 5 x 10 aluminum sheet, 48‘ x 96’ aluminum sheet, 1219 * 2438mm, 1220mm x 2440mm aluminum sheet, 1000mm x 2000mm aluminum sheet, 1250mm x 2500mm, 1219 x 2438mm, 1524 x 3048mm, 1500mm x 3000mm aluminum sheet.

- – Surface Finish: Mill finish (unless otherwise specified), Color Coated, or Stucco Embossed

- – Surface Protection: Paper interleaved, PE/PVC filming (if specified)

- – Minimum Order Quantity: 3MT

In addition to the commonly used specifications, Tigers Aluminum can also produce 3005 ultra-wide and ultra-thick aluminum plates with internal stress relief and no deformation during cutting, and the width is 2650mm, the thickness is 500mm.

3000 series aluminum sheets/plates:

3003 aluminum metal plate is an alloy plate commonly used in 3000 series aluminum plates. Other alloys in this series include the following:

- 3003 aluminum sheet

- 3004 aluminum sheet

- 3005 aluminum sheet

- 3104 Aluminum Sheet

- 3105 aluminum sheet

- 3A21 Aluminum Sheet

3105-H14 Aluminum vs. 3105-H24 Aluminium

Both 3105-H14 aluminum and 3105-H24 aluminum are variants of the same material. They share alloy composition and many physical properties, but develop different mechanical properties as a result of different processing.

3105-H24 aluminum is 3105 aluminum in the H24 temper. To achieve this temper, the metal is strain hardened, and then partially annealed, to a strength that is roughly halfway between annealed (O) and full-hard (H28).

workers are packing aluminum sheets

Comparison of 3105 aluminum with other alloys

Aluminum 3105 metal vs 3003 and 1100 aluminium metal

3105 aluminum has slightly higher strength than 3003 aluminum, others properties are similar to 3003 aluminum alloy, good conductivity, electrical conductivity can be up to 41%.

Aluminum alloy 3105 is essentially a 98% aluminum alloy with minor additions to increase strength over that of alloy 1100 aluminum and 3003.

3105 aluminum alloy vs 6061 aluminium alloy

Aluminum 3105 alloy has good forming characteristics. It is suggested that bend radii should be used in one thickness to 2 t range for annealed H12, H14 and H16 tempers. Bend radii of 2 to 7t should be used for the H18 temper.

6061 aluminum sheet alloy is strong, easily machined, and weldable. Aluminum 6061 T6 alloys are doubled the strength of aluminum 6063 alloys.

T651 temper has similar mechanical properties. The famous Pioneer plaque was made of this particular alloy.

Order 6061 Aluminum Sheets in 6061 Aluminum in small quantities and no minimums of all Aluminum 6061 at Tigers aluminum.

3105-h14 painted aluminum sheet

It is suitable for painting/coating and is commonly used for sign making, residential siding, mobile homes and in sheet metal work.

We offer 3105 painted aluminum sheet in pre-cut sizes from 12” x 48” up to 48” x 96”, with a variety of colors available.

Note: White on both sides and has a removable protective film on one side.

Standard & Specifications of 3105 aluminum sheet/plate/coil

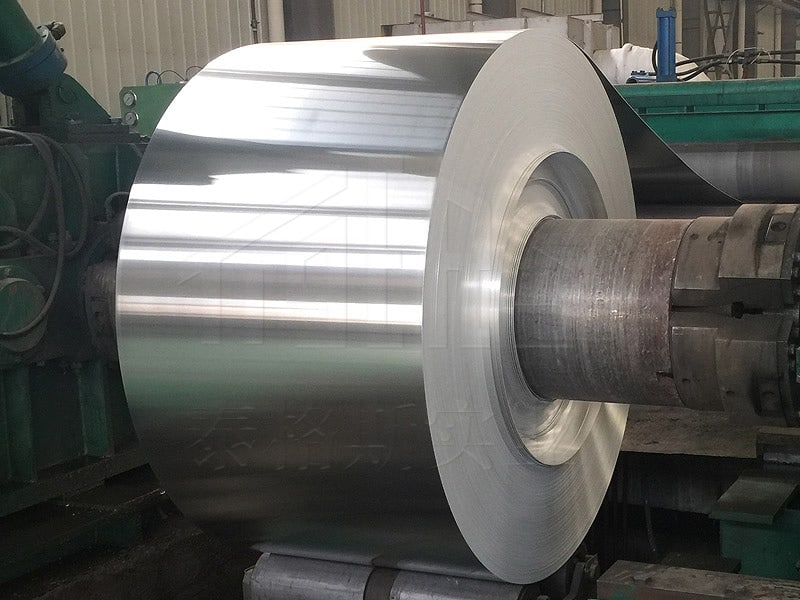

slitted 3105 aluminum coil

The following specifications cover Aluminum 3105

- ASTM B 209: Standard Specification for Aluminium and Aluminium-Alloy Sheet and Plate

- ASTM B 221: Standard Specification for Aluminium and Aluminium-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

- ASTM B 547: Standard Specification for Aluminium and Aluminium-Alloy Formed and Arc-Welded Round Tube

- ISO 6361: Wrought Aluminium and Aluminium Alloy Sheets, Strips and Plates

The material temper of aluminium 3105 are O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36and H38. The thickness is 0.1-500 mm, the width is 100-2600 mm, the length is 500-16000 mm. The typical final product are bottle cover, beverage bottle cap, cosmetic cover, etc. The market applications include room partition, baffle, movable room board, gutter and downpipe, sheet forming parts, bottle stopper, etc.

Aluminum Alloy 3105 is available in Sheet and Strip. For all stock availability of Aluminium 3105 contact Sales.

Why choose Tigers’s 3015 aluminum?

- Best Prices For Alloy 3015 Aluminium Sheet and Coil – Supplied Worldwide with Shortest Delivery Time.

- Exporting ASTM, EN Standard Compliant Aluminium 3015 sheet is Our Specialty.

- We are a factory, we manufacturer, supplier, wholesale and stockist of 3015 aluminum sheet, which can be cut to the size you need and shipped quickly via overseas warehouses and international logistics, giving you the “near me” experience and peace of mind with after-sales service.

- We Can Handle the Logistics for You – We can offer Exworks, FOB, CFR, CIF Delivery to Any Port.

- Documents We Provide Include – Certificate of Origin, Invoice & PL Attested by Chamber of Commerce, Test Certificates, Other Testing Reports, as may be Required by Our Customers.

The high quality 3015 aluminum sheet produced by Tigers aluminum conforms to AMS QQ-A-250/2 and ASTM B209, 3015 sheet stock is available in full size and custom cut lengths.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.