What is 3104 aluminum?

3104 aluminum alloy main alloying addition is manganese, 3104 aluminum has high tensile strength ≥ 275Mpa, elongation up to 20%, excellent deep drawing and ductility. The most common application in life is the aluminum can body material for beverage and beer cans.

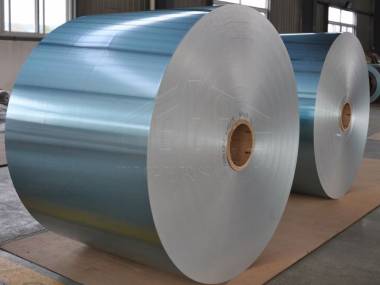

3104 aluminum coil production

3104 aluminium sheet is a 3000-series aluminum alloy, the main state is H19/H111/0/H14/H16/H18/H34.

Other names for 3104 aluminum alloy

3104 is the Aluminum Association (AA) designation for this material. In European standards, it will be given as EN AW-3104. AlMn1Mg1Cu is the EN chemical designation. Additionally, the UNS number is A93104.

Tigers aluminum is aluminum sheet plate 3104 manufacturer. 3104 aluminium is usually made into aluminum coils for sale, some users need to customize the size, we can also cut to size 3104 aluminium sheets or thicker aluminum plate.

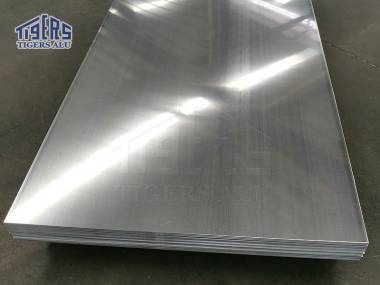

3104 aluminum sheet

3104 aluminum coil/sheet/plate chemical composition

Chemical Composition conforms to Chinese, American, and European standard specification

| Alloy | Manganese (Mn) |

Magnesium (Mg) |

Iron (Fe) |

Silicon (Si) |

Copper (Cu) |

Zinc (Zn) |

Titanium (Ti) |

Vanadium (V) |

Gallium (Ga) |

Residuals | Aluminum (Al) |

| 3104 | 0.8-1.4 | 0.8-1.3 | ≤0.8 | ≤0.6 | 0.05~0.25 | ≤0.25 | ≤0.1 | ≤0.05 | ≤0.05 | ≤0.15 | 95.1-98.4 |

3104 aluminum properties

3104 aluminum belongs to the deformation of aluminium alloy, with a high tensile strength ≥275 Mpa, and up to 20% elongation, thus showing excellent deep impact and processing ductility.

Besides, 3104 aluminium sheet is also a typical 3-series Al-Mg alloy. Due to the content of the main alloy Mg, 3104 aluminium alloy has very good corrosion resistance, excellent anodizing effect, no low-temperature brittleness, strong weather resistance, etc.

aluminium can and end

It has the lowest electrical conductivity among the 3000-series alloys.

What is the density of 3104 aluminum?

The density of 3104 aluminum is 2.72 g/cm³, in pounds and inches, it is 0.0983lb/in³.

3104 aluminum coil tensile strength & yield stress

Tensile strength of 3104-h19 aluminum is 290 MPa, yield stress is 260 MPa.

Aluminum 3104-h19 has good maleability, and up to 20% elongation.

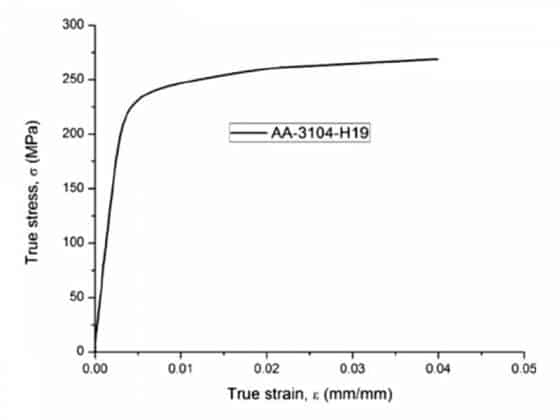

Aluminum 3104 H19 Stress Strain Curve

aluminum 3104 h19 stress strain curve

3104 aluminum Poissons Ratio

Poissons Ratio of 3104 aluminum is 0.34.

Physical Properties Datasheet

| Physical Properties | Metric | English |

| Density | 2.72 g/cc | 0.0983 lb/in³ |

Mechanical Properties Datasheet

| Mechanical Properties | Metric | English |

| Hardness, Brinell | 78 | 78 |

| Hardness, Knoop | 101 | 101 |

| Hardness, Vickers | 88 | 88 |

| Tensile Strength, Ultimate | 290 MPa | 42100 psi |

| Tensile Strength, Yield | 260 MPa | 37700 psi |

| Elongation at Break | 4.00% | 4.00% |

| Modulus of Elasticity | 69.0 GPa | 10000 ksi |

| Poissons Ratio | 0.34 | 0.34 |

| Shear Modulus | 26.0 GPa | 3770 ksi |

| Shear Strength | 175 MPa | 25400 psi |

Moduduls of elasticity of aluminum alloy 3104-h19

The elasticity modulus of aluminum alloy 3104-h19 can reach 69.0GPa

Shear strength of aluminum 3104

Shear strength of aluminum 3104 is 26.0GPa

Electrical Properties Datasheet

| Electrical Properties | Metric | English |

| Electrical Resistivity | 0.00000400 ohm-cm | 0.00000400 ohm-cm |

Thermal Properties Datasheet

| Thermal Properties | Metric | English |

| CTE, linear | 23.8 µm/m-℃ | 13.2 µin/in-℉ |

| 25.4 µm/m-℃ | 14.1 µin/in-℉ | |

| Specific Heat Capacity | 0.880 J/g-℃ | 0.210 BTU/lb-℉ |

| Thermal Conductivity | 170 W/m-K | 1180 BTU-in/hr-ft²-℉ |

| Melting Point | 630 – 655℃ | 1170 – 1210 ℉ |

| Solidus | 630℃ | 1170 ℉ |

| Liquidus | 655℃ | 1210 ℉ |

References for this datasheet:

Metals Handbook, Howard E. Boyer and Timothy L. Gall, Eds., American Society for Metals, Materials Park, OH, 1985.

Information provided by The Aluminum Association, Inc. from Aluminum Standards and Data 2000 and/or International Alloy Designations and Chemical Composition Limits for Wrought Aluminum and Wrought Aluminum Alloys (Revised 2001).

3104 Aluminum Coil Dimensions and Specifications

| 名称 | Can body | Can stock | Can stock | Can stock | Tap stock |

| Alloy series | 3104 aluminum | 3104 aluminum | 5052 aluminum | 5182 aluminum | 5182 aluminum |

| Type | DC(hot-rolled) | ||||

| Temper | F | ||||

| Coil ID(mm) | 605 | ||||

| Coil OD(mm) | ≤2600 | ||||

| Thickness(mm ) | 2.0-8.0 | 2.0-8.0 | 2.5-8.0 | 2.7-8.0 | 2.7-8.0 |

| Width(mm ) | 950-2100 | 950-2100 | 950-2100 | 950-2000 | 950-2000 |

| 名称 | Can body | Can stock | Can stock | Can stock | Tap stock |

| Alloy series | 3104 aluminum | 3104 aluminum | 5052 aluminum | 5182 aluminum | 5182 aluminum |

| Type | CC(Casting rolling) | ||||

| Temper | H19 | ||||

| Coil ID(mm) | 405、505、605 | ||||

| Coil OD(mm) | ≤2600 | ||||

| Thickness(mm ) | 0.24-0.38 | 0.22-0.28 | 0.22-0.28 | 0.218-0.28 | 0.26-0.46 |

| Width(mm ) | 700-2000 | 400-2000 | 400-2000 | 400-1800 | 700-1800 |

0.25 aluminum coil

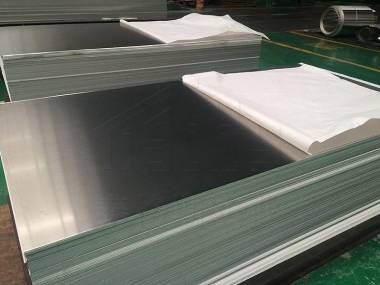

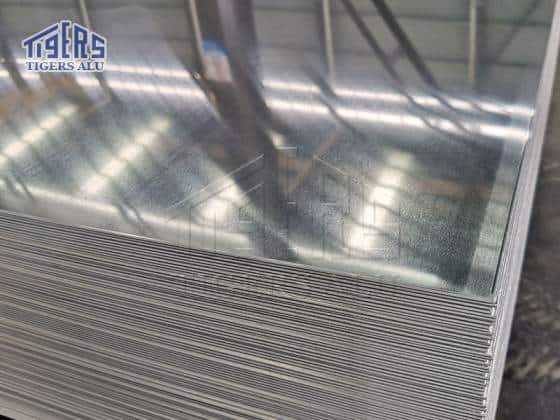

Tigers Aluminum as a factory and supplier of 3104 aluminum, produces 3104 aluminum coils/sheet/plate with high thickness accuracy, good deep drawing performance, excellent surface and mechanical properties.

aluminum bottle cap

Application Of 3104 Aluminum Sheet Roll

The 3104 aluminum sheet is mainly used in a variety of cans or cans lid.Such as, cookies, snacks and other dried food easy open end, all kinds of fish, meat food and other can body. In addition, it is also used in building materials, blinds, lamp cap materials, heat sink, makeup board, kitchenware and so on.

- 3104 aluminum coil mainly Used for processing the component parts that need to have good formability, high solderability good resistance to corrosion , such as kitchen utensils and appliances, food and chemical products processing and storage devices, transport tank, tank of liquid products.

- 3104 aluminum coil mainly used in chemical production and storage equipment, plate processing,building materials, construction, cable pipes, sewer pipes, various parts of lamps and lanterns, cans,wave plate, building materials, color aluminum plate, electric light head.

- 3104 aluminium coil mainly used in processing pressure vessel,pipeline,utensil,cooling fin,radiator,makeup board,copy machine roller,ship material,aluminium pors,aluminium can,light bulb lids.

The material to make aluminum cans is usually 3104 H19 aluminum alloy

The 3104 H48 aluminum alloy has a higher strength and is used as the material for aluminum can end.

Video

3104 H19 aluminum

3104 H18 aluminum has excellent deep-drawing properties and ductility, and is often used to make aluminum cans, such as beer cans and aluminum beverage cans.

What is aluminum can(beverage can)?

An aluminum can (British English: aluminium can), is a single-use container for packaging made primarily of aluminum.

3104 H48 aluminum

3104 H48 aluminum has a higher strength than 3104 H19 and is a superior material for producing aluminum can end.

How to buy 3104 aluminum sheet coil?

Tigers aluminum has more than 17 years experience in manufacturing 3104 aluminum sheet, in the international market we wholesale 3104 aluminum sheets and coils of various sizes, we also supply these products in China, support OEM and ODM services, Bulkbuy metal cut to size 3104aluminum sheet from Tigers aluminum, get the exact size you need.

3104 h19 aluminum coil

For the MOQ, stock, price list, size and other information of 3104 aluminum sheet, please leave a message or email to contact our sales staff to get the latest pricelist.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.