What is the 6063 aluminum sheet?

6063 aluminum sheet is a go-to material for projects where a sleek appearance, corrosion resistance, and moderate strength are essential. Often dubbed “architectural aluminum,” it’s a favorite in construction, furniture, and decorative applications.

Chemical Composition

6063 aluminum is primarily composed of aluminum, with magnesium and silicon as the main alloying elements. This composition contributes to its favorable mechanical properties and corrosion resistance.

| Cu | Si | Fe | Mn | Mg | Zn | Cr | Ti | Al | Other Each | Others Total |

| 0.10 (max) | 0.20/0.60 | 0.35 (max) | 0.10 (max) | 0.45/0.90 | 0.10 (max) | 0.10 (max) | 0.10 (max) | Remainder | 0.05 | 0.015 |

3mm h14 6063 aluminum sheet

Mechanical Properties by Temper

The mechanical properties of 6063 aluminum can vary depending on the temper (heat treatment) applied.

| Temper | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Brinell Hardness |

| O | 89.6 | 48.3 | 21 | 25 |

| T4 | 172 | 89.6 | 17 | 46 |

| T5 | 186 | 145 | 11 | 60 |

| T6 | 241 | 214 | 11 | 73 |

These properties make 6063 aluminum suitable for applications requiring moderate strength and excellent finish.

Mechanical Properties of Aluminium 6063 sheets / Plates

| Tensile Strength (psi) | Yield Strength (psi) | Elongation (% in 2″) | Brinell Hardness |

| 27,000 | 21,000 | 12 | 60 |

Key Features

- Excellent Surface Finish: Ideal for anodizing, resulting in a smooth, attractive appearance.

- Good Corrosion Resistance: Performs well in various environments, including marine settings.

- High Extrudability: Easily formed into complex shapes, making it versatile for various applications.

- Moderate Strength: Sufficient for many structural applications without being overly heavy.

Typical Applications

- Construction: Window frames, door frames, curtain walls, and architectural trims.

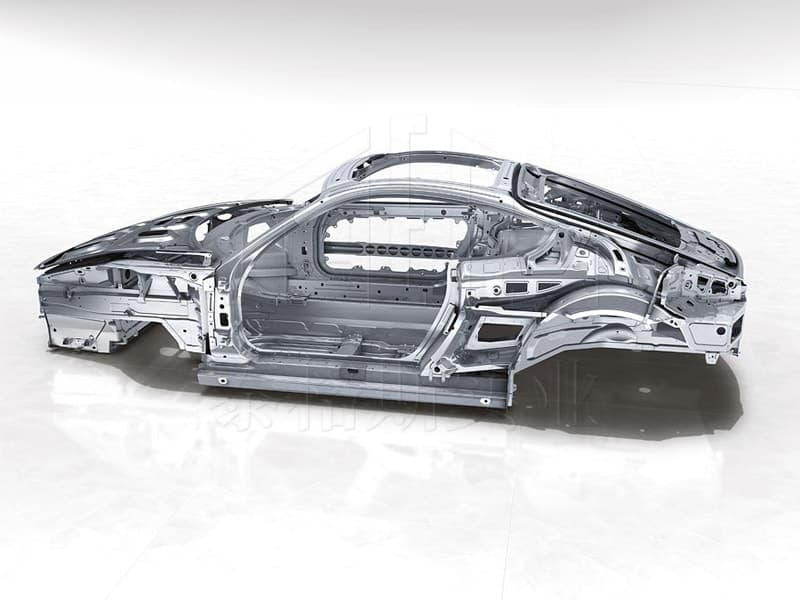

- Automotive: Body panels, engine components, and trim parts.

- Electronics: Heat sinks, housings, and structural components.

- Marine: Boat hulls, decks, and other components exposed to saltwater.

- Aerospace: Fuselage panels and wing structures where weight savings are crucial.

For a deeper dive into the differences between 6061 and 6063 aluminum sheets, you might find this resource helpful:

6063 vs. 6061 Aluminum: What’s the Difference?

While both 6063 and 6061 are part of the 6xxx series, they have distinct differences:

- Strength: 6061 offers higher strength and is better suited for structural applications.

- Surface Finish: 6063 provides a smoother surface, making it ideal for anodizing and decorative purposes.

- Corrosion Resistance: Both alloys offer good corrosion resistance, but 6063 has a slight edge in certain environments.

- Applications: Choose 6061 for load-bearing structures and 6063 for aesthetic applications.

Alucn supply 6063 aluminum plate, sheet and coil with special tempers developed for unique applications,Pass SGS certification, support third-party inspection.

auto shell made of aluminum sheet

More detail of 6061 aluminum sheet/plate

6063 aluminum sheet stands out for its excellent combination of formability, corrosion resistance, and surface finish. Whether you’re working on architectural projects, automotive components, or marine applications, 6063 offers a reliable and aesthetically pleasing solution.