What is aluminum can?

Aluminum can is a disposable recyclable packaging container made of metallic aluminum. It is often used for the hermetic packaging of beverages and food products, but can also be used for the packaging of oils, chemicals and other liquids.

The most common aluminum cans used in life are beer and beverage cans and canned goods. Aluminum cans are also the largest single use of aluminum.

aluminum can body and end

A common alloy used for aluminum can body is 3104 H19 aluminum.

What is aluminum can end?

An aluminum can end, also known as an aluminum can lid, is a metal closure made of aluminum used to seal the opening of an aluminum can.

Commonly used alloys are 5182 H48 aluminum, 5052 H48 aluminum, 5042 H48 aluminum, 3104 H48 aluminum.

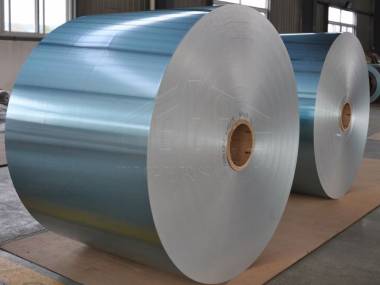

5042 H48 can end aluminum coil

5042 H48 aluminum coil is 5042 aluminum alloy tempered to H48 state, it is often used to make aluminum can end.

5182 H48 aluminum coil for can end

5182 H48 aluminum coil is 5182 aluminum alloy tempered to H48 state aluminum can end material, it is used to make can beverage, beer and food packaging lid

5052 H48 aluminum coil for can end

Tigers Aluminum is a supplier of 5052 H48 aluminum coil for can end, which is strong, easy to form, and corrosion resistant.

3104 H48 aluminum coil for can end

3104 H48 aluminum coil is commonly used in the production of aluminum can end, such as beverage cans, beer cans and other products can lids.

3104 H19 aluminum coil for can body

3104 H19 aluminum is a type of aluminum product made from 3104 aluminum alloy tempered to the H19 state, which is often used as aluminum can body material for beverage cans, beer cans and cans.

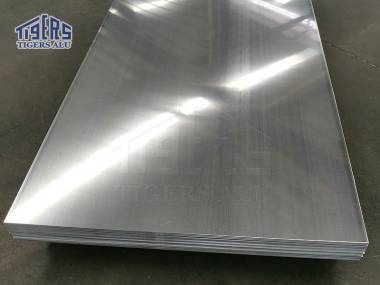

5182 aluminum sheet

5182 aluminum alloy can be used as can lid material. Tigersalu is a manufacturer and stockist of 5182 aluminum sheet / coil in China with reasonable price and best quality.

3104 aluminum

3104 aluminum alloy main alloying addition is manganese, it has high tensile strength ≥ 275Mpa, elongation up to 20%, excellent deep drawing and ductility. The most common applications are beverage cans and beer cans.

Why is aluminum material used for cans?

Aluminum, with its special mechanical and chemical properties, has become the material of choice for metal cans.

- Aluminum, in contrast to other metals, has greater ductility, which makes it easy to manufacture cans.

- Aluminum has a lighter weight, which makes it easier to transport and use.

- Aluminum has a better corrosion resistance, which ensures

- Aluminum raw materials are strong and can withstand high pressure.

- Aluminum cans are the most valuable recyclable material in life.

Why use 3104 H19 as a can material for aluminum cans body?

There are several reasons for using 3104 H19 as a can body material for aluminum cans.

- Good strength and ductility: 3104 H19 aluminum alloy has good strength and ductility deep punching, not easy to tear, can easily form the can shape during molding and processing, and can withstand the stress and pressure in transportation and use.

- Good corrosion resistance: 3104 H19 aluminum alloy has excellent corrosion resistance and can be used in wet and corrosive environments for long periods of time without affecting its appearance.

- Recyclability: Aluminum cans are a recyclable packaging material. Aluminum cans made from 3104 H19 aluminum alloy can be recycled and reused to reduce environmental pollution.

- Cost effectiveness: 3104 H19 aluminum alloy is relatively low cost compared to other metals and alloys, which can provide the best cost effectiveness for can making companies.

In summary, the 3104 H19 aluminum alloy is well suited as a can material for aluminum cans because of its good formability, corrosion resistance, recyclability and cost effectiveness.

Strength of raw materials for aluminum cans

Aluminum cans require a certain amount of strength to seal the objects inside. For example, beer cans and carbonated beverage cans, where the liquid is rich in carbon dioxide, can exert a lot of pressure on the walls of the can.

The raw material for aluminum cans is manufactured by adding other metals such as magnesium or by annealing to increase strength.

Materials suitable for manufacturing aluminum can end

5182 H48 aluminum, 5052 H48 aluminum, 5042 H48 aluminum, 3104 H48 aluminum alloys are chosen by can makers and used as raw materials for aluminum can end.

They are all aluminum alloy products in H48 state and all have the following common properties.

Similarities

- Good strength and ductility

- Good corrosion resistance

- recyclability

Differences

- 3104 H48 alloy is more suitable for stamping and drawing processing

- 5052 H48 alloy is more suitable for high strength applications

- 5182 H48 alloy is suitable for high speed forming processes, etc.

Read More:

What alloys can be used to make aluminum can end?

According to the above characteristics, different aluminum alloys should be used in different applications as the can material for aluminum cans.

Packing

Aluminum products of Tigers meet the export popular.Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.