Wood grain aluminum trim coil is the most commonly used building material in recent years. Wood grain aluminum trim coil can be produced by thermal transfer or roller coating with is a simple construction process and convenient installation. It is commonly used in external walls and ceilings.

The raw material of wood grain aluminum trim coil is 3000 series and 5000 series alloy aluminum coil, which can be coated with fluorocarbon or PE paint on one or both sides. The pattern and color can be customized and the life is more than 25 years.

Tigers aluminum is a wood grain aluminum trim coil manufacturer with competitive prices and specifications that can be customized according to project needs.

wood grain aluminum trim coil

The wood-grain paint layer is made of polyester resin paint, roller-coated wood grain paint, and transparent protective paint which is made of polyester resin varnish and dried by roller coating.

Advantages of wood grain aluminum trim coil

Wood grain aluminum trim coil The wallboard used as a machine tool decoration has an antistatic function, at the same time, it does not dust, does not accumulate, and is easy to clean. It is simple to disassemble and easy to construct.

Alloy Designation (For Reference)

Comparison of Alloy Designations for Aluminum Flat Products

| Alloy | Chinese Standard | American Standard | European Standard |

| 1xxx Series | 1050 | – | – |

| 1050A | – | EN AW-1050A | |

| 1100 | 1100 | – | |

| 3xxx Series | 3003 | 3003 | EN AW-3003 |

| 3105 | 3105 | EN AW-3105 | |

| 5xxx Series | 5005 | 5005 | EN AW-5005 |

| 5052 | 5052 | EN AW-5052 |

Aluminum sheet pre-roll coating process

Tigers paint solid color, wooden grain, brushed, marble grain, chameleon etc thick sheet painting production line.

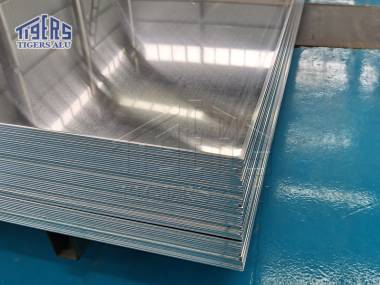

Wood grain aluminum trim coil specifications

| material | A1100, A3003, A3004,A3105,A5052,A8011……. |

| coating thickess | PVDF、PE、Epoxy varnish thickness |

| thickness of aluminum sheet | 0.2mm-4.00mm(0.2-1.0mm for coil, 1.0-6.0mm for sheet) |

| width color | color coated aluminum coil 20mm-1500mm |

| color coated aluminum sheets 800-1750mm | |

| core diameter | 150mm,405mm, 505mm, 508mm, 510mm |

| coating thickness | PVDF≥micron |

| POLYESTER≥18micron | |

| luminosity | 10-90% |

| hardness of the coating more | more than 2H |

| adhesion | no lower than 1 grade a splash |

| lash-bearable | 50kg/cm No paint peeling, no cracks. Polyester color is used for 20 years, and fluorocarbon is used for 30 years. |

| colors color | Color according to RAL and Pantone color chart or customer samples |

Wood grain aluminum trim coil Base Material Thickness Testing Standard

The thickness of the substrate should be measured at least at the four corners and the five center points of the sample.

woodgrain look aluminum coil production line

Use a thickness measuring instrument with a minimum scale of 0.001mm to measure the total thickness of a certain point, and then measure the local film thickness at that point in accordance with the provisions of GB/T4957, and take the difference between the total thickness and the local film thickness as the base material at that point thickness. Take the limit deviation between all measured values and the nominal value as the test result.

Multi-layer painting process

Multilayer spraying process with three sprayings (referred to as three sprays), spray bottom paint, topcoat and hood varnish and two sprayings (primer, topcoat).

Coating thickness: It can be divided into single coating (4μm-20 μm); double coating (25μm-28 μm); 3 coating (35μm-38μm).

The coating of wood grain aluminum trim coil has many excellent characteristics such as high durability, anti-fading, thermal insulation and corrosion protection, antibacterial, antistatic, self-cleaning, preservative etc.

In recent years, under the promotion of environmental protection and energy-saving building concepts, wood grain aluminum trim coil has clear texture and realistic imitation wood grain effect, it also has the characteristics of fire prevention, corrosion resistance, easy molding, convenient construction, maintenance-free, high recycling value, etc. It becomes a new type of building material.

light brown aluminum coil wood grain

Wood grain aluminum trim coil Hydrochloric Acid Resistance Test Standard

The end of the glass tube with an inner diameter no less than 50rrnn is bonded to the center of the test coating surface with vanilla so that the contact is well sealed, and the volume fraction of pouring is 2% (for indoor use) or 5% (for outdoor use) ) Hydrochloric acid (HC1) solution, make the height of the liquid level 20mm±2mm, cover the tube tightly with a glass slide, take off the sample after standing for 24h, wash and dry, visually check whether there is blistering, discoloration, or peeling at the test site for abnormal phenomena, take the worst performance among the three samples as the test result.

Color aluminum produce parameter

| Item | Alloy | Temper | Coating thickness | Base aluminum thickness | Base aluminum width |

| Imitation Wooden Aluminum Coil/Sheet | 1060/1100/3003/3004/5052 or as per customer’s requests | H24 or customize | Above 25μm | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Imitation Stone Aluminum Coil/Sheet | 1100/3003/3004/5052 or as per customer’s requests |

H24 or customize | Above 35μm | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Brushed Aluminum Coil/Sheet | 1050/1060/1100 or customize | H24 or as per customer’s requests | Above 20μm or customize | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Stucco/ Embossed Aluminum Coil/Sheet | 1xxx,3xxx and 5xxx or customize | H24 or customize | As per customer’s requests | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Film Coated Aluminum Coil/Sheet | 1050/1060/1100/3003/5052 or as per customer’s requests | H24 or customize | As per customer’s requests | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Gradient Color Coated Aluminum Coil/Sheet | 1060/1100/ 3003/3004 or as per customer’s requests | H24 or customize | Above 35μm | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

Application of wood grain aluminum trim coil

It is widely used in homes, shopping malls, office buildings, hotels, schools, factories, banks, conference halls, gymnasiums, exhibitions, subways, airports and other public places.

Walls and ceilings decorated like wood grain aluminum panels

Coated aluminum coil and sheet are more resistant to keep food fresh. Coated aluminum coil and sheet improve anticorrosive properties of aluminum, which are commonly used in food packaging, containers and cans. In addition, the application of coated aluminum coil and sheet embraces large industries including composite panels, ceiling, door, windows and electric appliances.

We also produce hemp patterns, blue sky patterns, White, light off-white, reticulated and other color coated aluminum coil products.

Adopting special processing technology to show the natural wood grain effect.

Wood grain aluminum sheet decorative wall

The coating surface has been specially treated to prevent surface scratches and ultraviolet radiation.

A variety of wood grain color options to meet different needs.

Wood grain aluminum trim coil has become a very common product for the decoration of exterior walls and ceilings. It has strong decoration, real effect, wood texture, waterproof and fireproof, non-toxic and harmless all environmental protection materials, direct sales from manufacturers, and low price.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.