Henan Tigers Industry Co., Ltd. is a large-scale manufacturer of PVDF coated aluminum coil in Henan. It uses high-quality aluminum alloy as the material. The products are processed and produced in strict accordance with national standards. The quality is different from ordinary aluminum and galvanized PVDF coated aluminum coil, the coated layer is made of high-quality polyester fluorocarbon (PVDF), PE, powder coating, and can be customized to the width, thickness, color, pattern, and pattern as customer’s requirment.We strictly control quality of products, so that shipped products per ton fulfill the national standard . Factory direct sales, low wholesale prices.

Tigers have a professional sales team to quickly calculate the quotation for you, and provide the price and information of PVDF coated aluminum coilon that day, PVDF coated aluminum coil of Tigers brand has agents and distributors in the five major regions of China, and exports to more than 80 countries around the world .

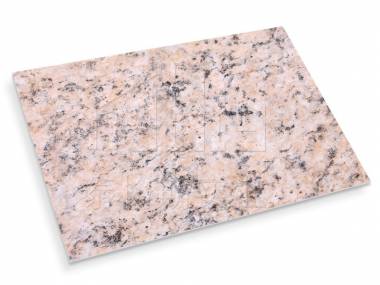

red PVDF coated aluminum coil stock

PVDF coated aluminum coil is a high-quality alloy and smooth color coated aluminum coil. After production processes such as cleaning, chromizing, rolling, baking, etc., paint coatings of various colors are attached to the surface of the aluminum coil.

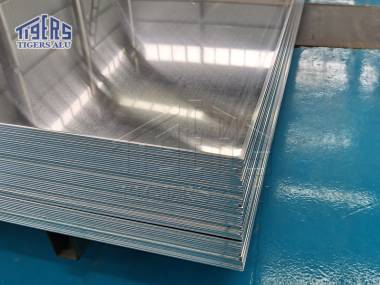

Transportation of PVDF coated aluminum coil

- Handle with care during transportation to prevent damage with the surface caused by collision,which affecting appearance.Covered with tarpaulin during transportation to avoid rain and snow.

- When transporting at high temperature, you can put desiccants in the middle or make holes on both sides, and make the color aluminum plating roller have breathable, you can also place an exhaust system, that to avoid the oxidation of the aluminum roller caused by the high temperature water droplets during transportation

- During transportation, we need to pay attention to the dry environment and good ventilation, and do not put it with corrosive products and other chemical substances, so as to cause unnecessary losses.

- When larger materials are stacked together, they should be separated by materials such as wooden strips to prevent frictional damage during stacking or picking.

The production, transportation and storage of PVDF coated aluminum coil all need to our employees and users to try it out as required. Many people think that their products will have problems quickly after used, which is a quality issue. In fact, except quality problems, it may also be ignored in a daily protection, so we need reasonable storage and transportation.

0.8mm white coated aluminum coil for ceiling

Production process of PVDF coated aluminum coil

Aluminum sheet pre-roll coating process

Tigers paints solid color, wooden grain, brushed, marble grain, chameleon etc thick sheet painting production line.

Multi-layer painting process

Multilayer spraying process with three spraying(referred to as three sprays), spray bottom paint, topcoat and hood varnish and two spraying (primer, topcoat).</>

Coating thickness: It can be divided into single coating (4μm-20 μm); double coating (25μm-28 μm); 3 coating (35μm-38μm).

The edges of the board should be cut neatly without burrs or cracks.

No open welding is allowed on the plate. The appearance should be neat and tidy, the pattern should be clear, the color should be basically the same, and there should be no obvious scratches. The decorative surface shall not have obvious indentation, imprints, bumps and other remnants.

No obvious color difference, AE is not greater than 2.0 in arbitration.

Video

Advantages of PVDF coated aluminum coil

Compared with ordinary building boards, PVDF coated aluminum trim coil with pvc film has the following characteristics:

- The texture is clear and beautiful, with a sense of fashion and technology.

- Excellent weather resistance, no deformation, long-lasting bright as new.

- Strong decoration, easy installation, wide application.

brick red coated aluminium coil

Regarding to PVDF coated aluminum trim coil, its qualitiy of the used materials, you need to check the workmanship and control for detail when buy the materials. Firstly, check the surface smoothness, whether the coating color is bright, and whether there is insufficient color. Secondly, the internal process control of the material is Not within own satisfaction.

Film or coating refers to the dry film of cured fluorocarbon paint on the metal substrate, also called coating.

The chemical properties of polyurethane coatings and polyester coatings are familiar, but they have special advantages in some aspects.

Polyurethane has high toughness, which is very important for color coated aluminum coils. At the same time, it has better scratch resistance than polyester.

Polyurethane is slightly more expensive than ordinary polyester coatings, and it has become a favored coating choice for high-end interior products such as home appliances.

| Item | Test Item | Standard | National standard | Test Result |

| 1 | Color Difference | ECCA T3 | ΔE≤2.0 | ΔE≤1.5 |

| 2 | Gloss Difference | ECCA T2 | ≤10 | ≤5 |

| 3 | Coating Thickness | ECCA T1 | Two layers Min 23μm | ≥25μm |

| Three layers Min 30μm | ≥34μm | |||

| 4 | Pencil Hardness | ASTM D3363 | ≥HB | HB |

| 5 | T-bend | ASTM D4145 | ≤2T | ≤2T |

| 6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | ASTM D2794 | ≥50kg.cm | ≥50kg.cm |

| 8 | Boiling water Resistance | GB/T17748 | 2h No change | 4h No change |

| 9 | Solvent Resistance | ASTM D2248 | 200 times paints remaining | 500 times no break |

| 10 | Acidity Resistance | ASTM D1308 | 5%HCL 24hrs No change | No change |

| 11 | Alkali Resistance | ASTM D1308 | 5%NaOH 24hrs No change color △E≤2.0 | No change |

| 12 | Nitric acid Resistance | AAMA620 | △E≤5.0 | △E≤5.0 |

| 13 | Oil Resistance | ASTM D1308 | 20#oil 24hrs No change | No change |

| 14 | Salt Spray Resistance | ASTM B117 | 4000hrs ≤Grade 1 | No change |

| 15 | Abrasion resistance | ASTM D968 | ≥5L/μm | ≥5L/μm |

| 16 | Dirt Resistance | GB/T9780 | ≤5% | <5% |

| 17 | Color retaining | GB/T16259 | 4000 hrs△E≤4.0 | 4000 hrs △E≤3.0 |

| 18 | Gloss weaken Level | 4000 hrs ≤ Grade 2 | 4000 hrs ≤ Grade 2 | |

| 19 | Chalking | 4000 hrs No change | 4000 hrs No change |

Henan Tigers Industry Co., Ltd. is committed to the production of PVDF coated aluminum coil, manufacturers wholesale and directly sales, the products are sold to many regions in China, and provide export trade services. In addition, our high-quality products such as imitation copper, sand effect, black are widely recognized and applied in the market, and the products have the advantages of [simple characteristics]. We freely provide you with price information of PVDF coated aluminum coil, delivery on time, low price, welcome to consult the quotation!

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.