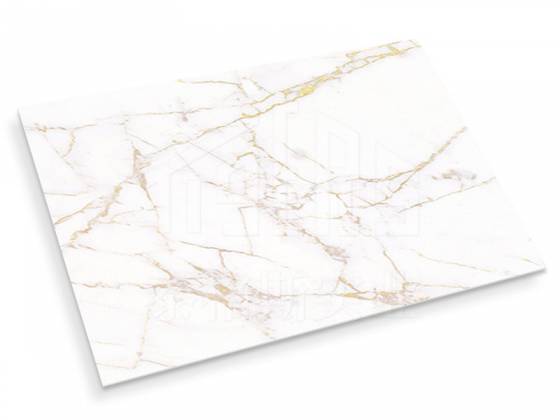

Marble look aluminum sheet is commonly used in curtain wall decoration. The texture is the same as that of the stone slab, it is a perfect substitute for the stone slab for construction.

Marble look aluminum sheet’s construction technology is simple, easy to install, while its service life is longer than that of stone slabs. It is much lighter than stone slab for the same square meters, and it can be recycled again.

For some special purposes, it can be deep processed into stone grain honeycomb aluminum plate, stone grain heat insulation aluminum plate, etc., and the surface is sprayed with marble and other stone grain lines.

Tigers are marbled look aluminum sheet manufacturer with low prices. All products can pass the national standard test and are used by many large projects such as Beijing and Shanghai.

marble grain coated aluminium sheet adopts 3D stone pattern effect and multi-color overprint, with strong three-dimensional sense, simple structure and cost saving, imitation stone aluminum sheet replace real marble effectively, reduces the damage to natural ecological resources, and it also can be recycled and reused.

Color aluminum produce parameter

| Item | Alloy | Temper | Coating thickness | Base aluminum thickness | Base aluminum width |

| Imitation Wooden Aluminum Coil/Sheet | 1060/1100/3003/3004/5052 or as per customer’s requests | H24 or customize | Above 25μm | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Imitation Stone Aluminum Coil/Sheet | 1100/3003/3004/5052 or as per customer’s requests |

H24 or customize | Above 35μm | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Brushed Aluminum Coil/Sheet | 1050/1060/1100 or customize | H24 or as per customer’s requests | Above 20μm or customize | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Stucco/ Embossed Aluminum Coil/Sheet | 1xxx,3xxx and 5xxx or customize | H24 or customize | As per customer’s requests | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Film Coated Aluminum Coil/Sheet | 1050/1060/1100/3003/5052 or as per customer’s requests | H24 or customize | As per customer’s requests | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Gradient Color Coated Aluminum Coil/Sheet | 1060/1100/ 3003/3004 or as per customer’s requests | H24 or customize | Above 35μm | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

Advantages of Marble look aluminum sheet

The ink that can be chosen is polyester, a fluorocarbon system, which has high weather resistance.

Compared with stone, it is suitable for stamping and bending, and it can be processed into various shapes.

Marble look aluminum sheet The texture is clear and lifelike.

Fluorocarbon aluminium panel painting process

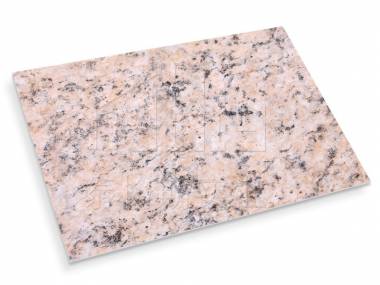

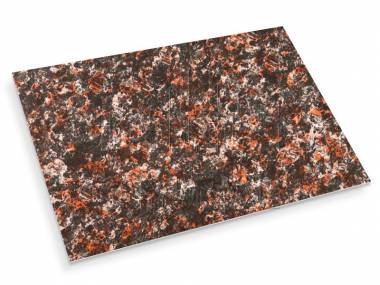

Blue, gold, hemp pattern, black are well received by customers.

granite coated aluminium coil sheet

Multi-layer painting process

Multilayer spraying process with three sprayings (referred to as three sprays), spray bottom paint, topcoat and hood varnish and twsprayingsng (primer, topcoat).</>

Coating thickness: It can be divided into single coating (4μm-20 μm); double coating (25μm-28 μm); 3 coating (35μm-38μm).

Ceramic coating is formed by baking a pigmented inorganic resin.

The inorganic resin is formed by a chemical reaction between a sol of metal oxide and a hydrolyzable metal alkoxide.

Marble look aluminum sheet is becoming more and more popular in the market with its outstanding advantages, lightweight and easy to clean, the surface stone pattern simulation degree reaches 95%.

granite coated aluminium coil sheet

Alloy Designation (For Reference)

Comparison of Alloy Designations for Aluminum Flat Products

| Alloy | Chinese Standard | American Standard | European Standard |

| 1xxx Series | 1050 | – | – |

| 1050A | – | EN AW-1050A | |

| 1100 | 1100 | – | |

| 3xxx Series | 3003 | 3003 | EN AW-3003 |

| 3105 | 3105 | EN AW-3105 | |

| 5xxx Series | 5005 | 5005 | EN AW-5005 |

| 5052 | 5052 | EN AW-5052 |

Application of Marble look aluminum sheet

Marble look aluminum sheet is widely used in the construction industry and has played an important role in the development of modern buildings in the direction of comfort, lightness, durability, economy and environmental protection. Due to the advantages of moderate structural strength, weather resistance, corrosion resistance, fire resistance, acid and alkali resistance, and heat insulation, it is recognized as a roofing and exterior wall material with a design service life of more than 20 years.

The coating of the Marble look aluminum sheet has many excellent characteristics such as high durability, preservative, high strength, antibacterial, thermal insulation and corrosion protection, long life, preservative etc.

Video

Marble look Coated aluminum coil and sheet is more resistant to keep food fresh. Coated aluminum coil and sheet improve anticorrosive properties of aluminum, which are commonly used in food packaging, containers and cans. In addition, the application of coated aluminum coil and sheet embraces large industries including composite panels, ceilings, doors, windows and electric appliances.

granite coated aluminium coil sheet

Marble look aluminum sheets produced by Tigers are widely used in curtain wall decoration, ceilings, columns, door heads, simple construction process, easy installation, the weight of each square aluminum plate is more than 70% lighter than the stone plate, high safety, wholesale price, the price advantage is obvious.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.