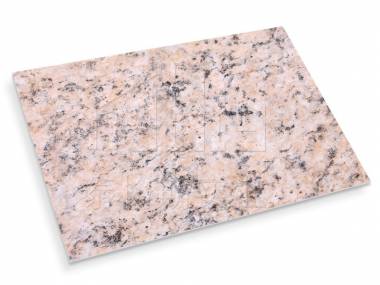

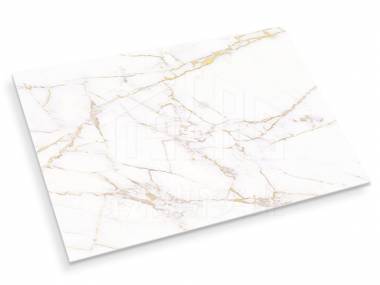

Aluminum metal stone honeycomb panel adopts the processing technology of spraying or roller coating, and the surface can also be sprayed with real stone paint, which is consistent with the real stone feel. Common stone patterns are curtain walls aluminum metal stone honeycomb panel, gray aluminum metal stone honeycomb panel, 3d aluminum metal stone honeycomb panel, brick pattern color coated aluminum plates, real stone painted aluminum veneers, etc., special patterns can be customized. Some thinner aluminum plates can be reprocessed, such as 0.5mm, can be made into honeycomb aluminum plates, thermal insulation aluminum-plastic composite plates, etc.

Aluminum metal stone honeycomb panel produced by Tigers are strictly installed in accordance with the national standard inspection. The stone texture is really bright and the same as the stone. It can completely replace the real stone curtain wall panel.

Aluminum metal stone honeycomb panel

Aluminum metal stone honeycomb panel can decorate curtain walls of various shapes.The artistic effects of stone patterns and marble treatment on the surface of the product are also very popular.* also has excellent weather resistance, UV resistance, acid rain resistance, alkali resistance, and self-cleaning properties.

Advantages of Aluminum metal stone honeycomb panel

Compared with ordinary building boards, Aluminum metal stone honeycomb panel has the following characteristics:

- The texture is clear and beautiful, with a sense of fashion and technology.

- Excellent weather resistance, no deformation, long-lasting bright as new.

- Strong decoration, easy installation, wide application.

- Lightweight, high strength, super rigidity and flexural strength.

- Sound insulation and heat insulation.

- Strong earthquake resistance and fireproof.

- Fine weather resistance and chemical resistance.

- Solid and durable, with natural beauty.

- Easy and secure installation, and put less load on buildings.

- Material saving, time-saving, labor-saving, and low installation cost.

- Custom made to the size and shape required for the specific project.

Fluorocarbon aluminium panel painting process

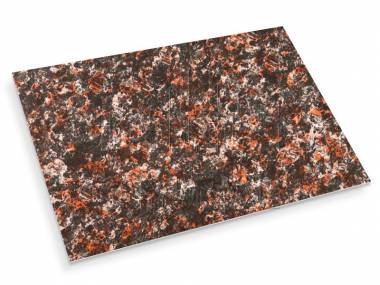

Green, dark green, light bean green, imitation brick pattern, blue sky pattern, hemp pattern, crimson, green grass pattern are well received by customers.

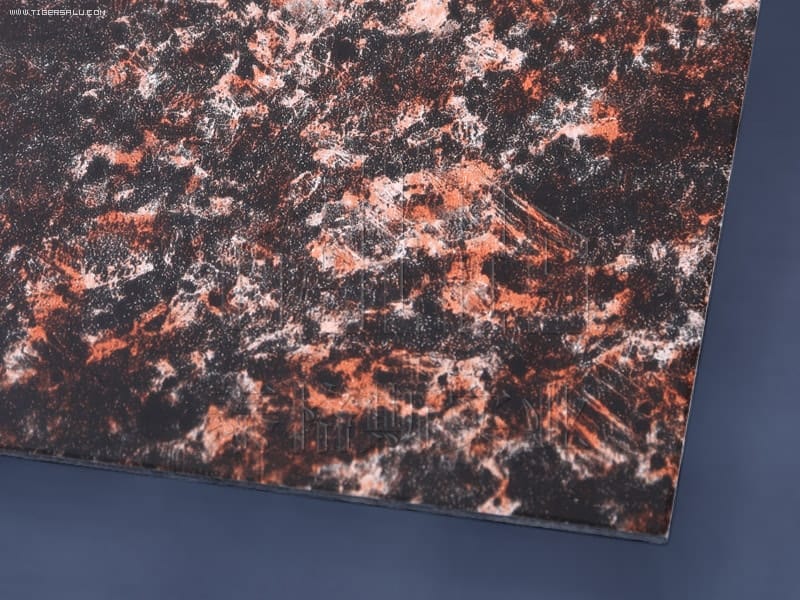

granite coated aluminium coil sheet

Multi-layer painting process

Multilayer spraying process with three spraying(referred to as three sprays), spray bottom paint, topcoat and hood varnish and two spraying (primer, topcoat).</>

Coating thickness: It can be divided into single coating (4μm-20 μm); double coating (25μm-28 μm); 3 coating (35μm-38μm).

The edges of the board should be cut neatly without burrs or cracks. No open welding is allowed on the plate.

The appearance should be neat and tidy, the pattern should be clear, the color should be basically the same, and there should be no obvious scratches.

The decorative surface shall not have obvious indentation, imprints, bumps and other remnants. No obvious color difference, AE is not greater than 2.0 in arbitration.

Aluminum metal stone honeycomb panel takes the aluminum plate as the base material, the surface processing USES the special craft to add the stone grain effect, makes it simulation stone feeling.

granite coated aluminium coil sheet

Product Specification and Size :

Standard Specification: YS/T 431, GB/T 17748, Mill’s standard, Mutually agreed standard, Base material conforms to GB/T 3880, ASTM B209 or EN 485.

| Alloy | Temper | Remarks |

| 1xxx: 1050, 1050A, 1100 | H42, H44, H46, H48 | ★Temper H12, H14, H16, H18, H22, H24, H32 and H34, for base material are provided as per client’s request and mutually agreed. |

| 3xxx: 3003, 3105 | ||

| 5xxx: 5005, 5052 |

Alloy Designation (For Reference)

Comparison of Alloy Designations for Aluminum Flat Products

| Alloy | Chinese Standard | American Standard | European Standard |

| 1xxx Series | 1050 | – | – |

| 1050A | – | EN AW-1050A | |

| 1100 | 1100 | – | |

| 3xxx Series | 3003 | 3003 | EN AW-3003 |

| 3105 | 3105 | EN AW-3105 | |

| 5xxx Series | 5005 | 5005 | EN AW-5005 |

| 5052 | 5052 | EN AW-5052 |

Available Size Range:

| Dimension | Range |

| Thickness | 0.25 ~ 1.8 mm |

| Diameter | 200 ~ 1,750 mm |

| Length | Coiled, or 2,000 ~ 4,000 mm |

*Cut to length service is available for thickness over 0.5mm

Application of Aluminum metal stone honeycomb panel

It is widely used in homes, shopping malls, office buildings, hotels, schools, factories, banks, conference halls, gymnasiums, exhibitions, subways, airports and other public places.

The coating of Aluminum metal stone honeycomb panelhas many excellent characteristics such as high durability, high weather resistance, fingerprint resistant, self-cleaning, high strength, anti-fading, preservative, thermal insulation and corrosion protection etc .

Stone veneer aluminum honeycomb panels can be used in commercial, hospitality, financial, government, educational and other functional construction projects throughout the world.

Architects can use the stone aluminum honeycomb panels for wall cladding, architecture façade cladding for exterior and interior of buildings, ceilings, soffits, column coverings, partitions, luxury furniture or cabinets. The lightweight panels are quick and easy to install, making them as the ideal material for fast-track project.

granite coated aluminium coil sheet

Aluminum metal stone honeycomb panel produced by Tigers are widely used in curtain wall decoration, ceilings, columns, door heads, simple construction process, easy installation, the weight of each square aluminum plate is more than 70% lighter than the stone plate, high safety, wholesale price, the price advantage is obvious.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.