8 Inch Aluminum Siding Wood Grain Overview

8 inch aluminum siding wood grain is the most commonly used building material in recent years.8 inch aluminum siding wood grain can be produced by thermal transfer or roller coating with is simple construction process and convenient installation. It is commonly used in external walls and ceilings.

Tigers aluminum is a 8 inch aluminum siding wood grain manufacturer with competitive prices and specifications that can be customized according to project needs.

8 inch aluminum siding wood grain

Wood look aluminum siding as a substitute for wood, it has the functions of corrosion resistance, insect resistance, fire resistance, etc.

It has higher strength than wood, and lighter unit weight, which is easy to transport.

The types of aluminum substrate alloys used in aluminum siding are as follows:

1100 alloy aluminum sheet

3004 alloy aluminum sheet

3105 aluminum sheet

5754 aluminum sheet

Quick Details

| Standard size | 8inch, 4″, 1220 x 2440 x 3mm and 1220 x 2440 x 4mm, Support customization |

|---|---|

| Accepted thickness | 2mm, 3mm, 4mm, 5mm, 6mm |

| Common width | 1220mm, 1250mm, 1500mm, 1575mm, 2000mm… |

| Accepted length | According to buyer’s requirement |

| Accepted alu thickness | 0.04~0.5mm, such as 0.06mm,0.10mm,0.15mm, 0.18mm,0.21mm,0.3mm,0.35mm,0.4mm, 0.45mm,0.5mm |

Product Specification and Size :

Standard Specification: YS/T 431, GB/T 17748, Mill’s standard, Mutually agreed standard, Base material conforms to GB/T 3880, ASTM B209 or EN 485.

| Alloy | Temper | Remarks |

| 1xxx: 1050, 1050A, 1100 | H42, H44, H46, H48 | ★Temper H12, H14, H16, H18, H22, H24, H32 and H34, for base material are provided as per client’s request and mutually agreed. |

| 3xxx: 3003, 3105 | ||

| 5xxx: 5005, 5052 |

Color coating

By function: PE & PVDF.

PE is used for interior, with 10 year life-long expectancy.

PVDF coating, with resistance on UV, acid and alkali, is more suitable for exterior usage, with 15-20 year guarantee.

Coating thickness

It can be divided into single coating (4μm-20 μm); double coating (25μm-28 μm); 3 coating (35μm-38μm).

Multi-layer painting process

Multilayer spraying process with three spraying(referred to as three sprays), spray bottom paint, topcoat and hood varnish and two spraying (primer, topcoat).

Video

Advantages of 8 inch aluminum wood grain siding

The ink can be choosen are PE, fluorocarbon(PVDF) system, which has high weather resistance.8 inch aluminum siding wood grain The texture is clear and lifelike, Compared with stone and wood, it is suitable for stamping and bending, and it can be processed into various shapes.

Aluminum sheet pre-roll coating process

Tigers paints solid color, wooden grain, brushed, marble grain, chameleon etc thick sheet painting production line.

Coating Properties

| Gloss | Gloss Range(%) 60° | Tolerance |

|---|---|---|

| Matt | 3~30 | ±5 |

| Satin | 31~70 | ±7 |

| Glossy | 71~100 | ±10 |

Mortar resistance test standard:

- Mix 75g of building quicklime powder conforming to JC/T 480 and standard fine sand in a ratio of 1:3, and filter with a 10-mesh filter.

- Add appropriate water to make a mortar and apply it on the surface of the paint film. Painted in a size of 50mm×25 mm, about 13mm thick.

- After placing the sample in an environment with a relative humidity of 95%±5% at 38℃±3℃ for 24h, remove the mortar and wipe off the residual ash with a damp cloth.

- The residual ash that cannot be removed can be removed with the 10% hydrochloric acid solution in section 5.9.1, and visually inspect the appearance after drying.

Color change performance test standard

According to GB/T 9276, after the sample has been exposed for 10 years, the discoloration with ?E of not more than 5NBS compared with the original color is qualified.

It can be directly measured with a computer colorimeter, and the average value of the points is taken. The measurement method is as following: after exposure, the sample is exposed to clean water and a damp cloth to remove the surface ash, and then the color change is measured.

At the same time, the same batch of unexposed samples is measured as a reference, and the color difference between the two is compared. Rinse the sample gently with water to remove the dust accumulation.

It is not allowed to wipe or polish hard to avoid removing the powder.

8 inch wood grain aluminum siding specifications

| Thickness | 1.5mm, 2.0mm, 2.5mm, 3.0mm, 4.0mm, 5.0mm(0.2-1.0mm for coil, 1.0-6.0mm for sheet) |

| Weave Style | Punching, engraving, embossing, hyperbolic, arc plate, modeling board |

| Type | Glass Wal, Facade Panel, Wall Panels |

| Application | Building, Outdoor, Ceiling ceiling |

| Material | Aluminum Alloy 1050/1060/1100/3003/3004/3105/5052/5754 |

| Exterior | customize |

| Usage | Building |

| Surface treatment | Fluorocarbon, painting, wood grain |

| Color | customize |

The coating of 8 inch aluminum siding wood grain has many excellent characteristics such as antibacterial, antistatic, self-cleaning, thermal insulation and corrosion protection, preservative, fingerprint resistant etc .

The above parameters can directly affect the cost of consumer purchases, and also include the aluminum ingot price at that time.

The aluminum price fluctuated in the market, so the cost of 8 inch aluminum siding wood grain also changes with at any time.

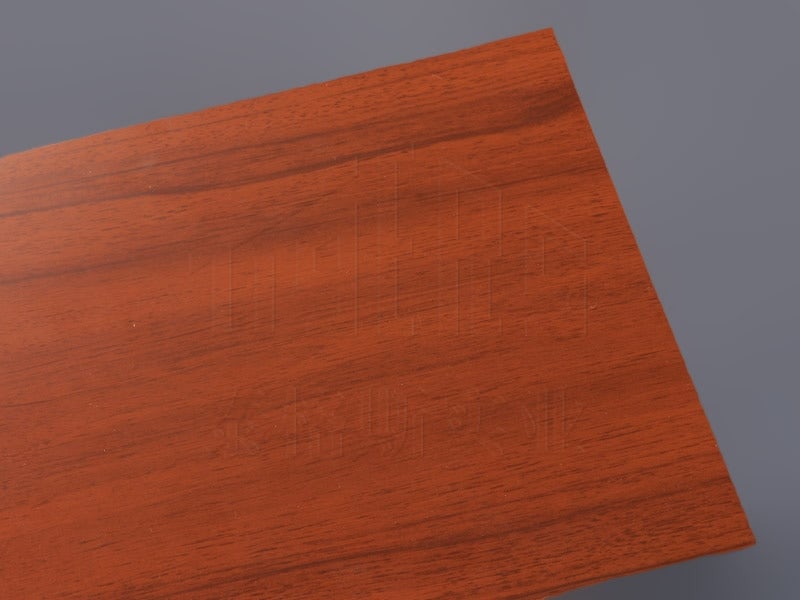

Red wood grain aluminum sheet

Application of 8 inch wood grain aluminum siding

Wood grain finish aluminum sheet from Tigers offers a nature timber appealing, environmentally friendly solution for many products in architectural building construction and home interior industry, such as windows and doors, curtain wall and facade, louvers, railing, decking, furniture, ceiling and cladding, house siding, garden fence and gate, cabinets, appliance, etc. The wood grain finish is ideally suited for applications where architects prefer to see a natural wood appearance.

8 inch aluminum siding wood grain is a commonly used material in construction. It can be used as a common material in industrial products such as hardware, air conditioners, decorations, and transformers, etc.

light wood grain aluminum sheet

We also produce red, silver, green grass pattern, plain, imitation copper, imitation copper and other color coated aluminum coil products.

Protective film

A layer of PE plastic tape, to protect the panel surface from scratch or damage. The thickness and sticky standard are various upon different supplier.

Color aluminum produce parameter

| Item | Alloy | Temper | Coating thickness | Base aluminum thickness | Base aluminum width |

| Imitation Wooden Aluminum Coil/Sheet | 1060/1100/3003/3004/5052 or as per customer’s requests | H24 or customize | Above 25μm | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Imitation Stone Aluminum Coil/Sheet | 1100/3003/3004/5052 or as per customer’s requests |

H24 or customize | Above 35μm | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Brushed Aluminum Coil/Sheet | 1050/1060/1100 or customize | H24 or as per customer’s requests | Above 20μm or customize | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Stucco/ Embossed Aluminum Coil/Sheet | 1xxx,3xxx and 5xxx or customize | H24 or customize | As per customer’s requests | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Film Coated Aluminum Coil/Sheet | 1050/1060/1100/3003/5052 or as per customer’s requests | H24 or customize | As per customer’s requests | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

| Gradient Color Coated Aluminum Coil/Sheet | 1060/1100/ 3003/3004 or as per customer’s requests | H24 or customize | Above 35μm | 0.25-1.35mm for coil,1.5-5.0mm for sheet | Min 30mm, Max 1350mm for coil,1850 for sheet |

8 inch aluminum siding wood grain Excellent weather resistance, abrasion resistance, corrosion resistance and other characteristics, with high hardness, not easy to deform, real wood imitation pattern does not fade, does not fall off, suitable for indoor and outdoor use in various occasions

8 inch aluminum siding wood grain is already common in daily life. The surface is made of aluminum alloy with fluorocarbon paint. It is designed according to the project site. It is highly customizable, easy to install, and has a long life. The wood grain aluminum plate produced by TIGERS produce it with National standards which are popular among people.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.