What is alloy 6082 aluminum sheet / plate?

Alloy 6082 aluminum plate sheet is a medium strength alloy with excellent corrosion resistance.It has the highest strength of the 6000 series alloys. Alloy 6082 contain magnesium and silicon as the major alloying elements.

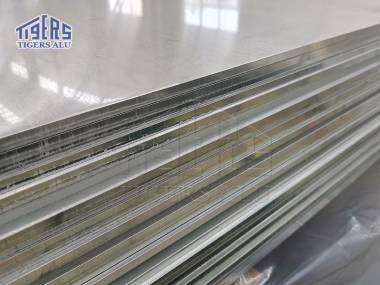

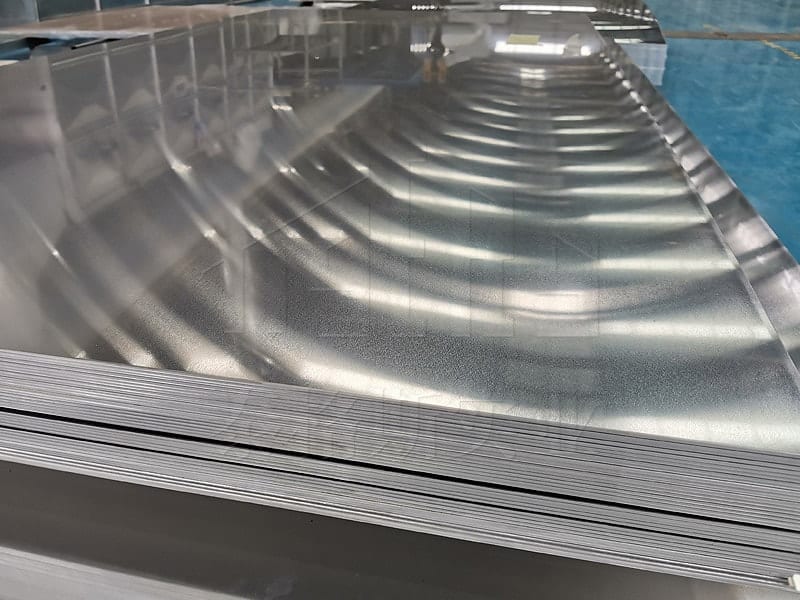

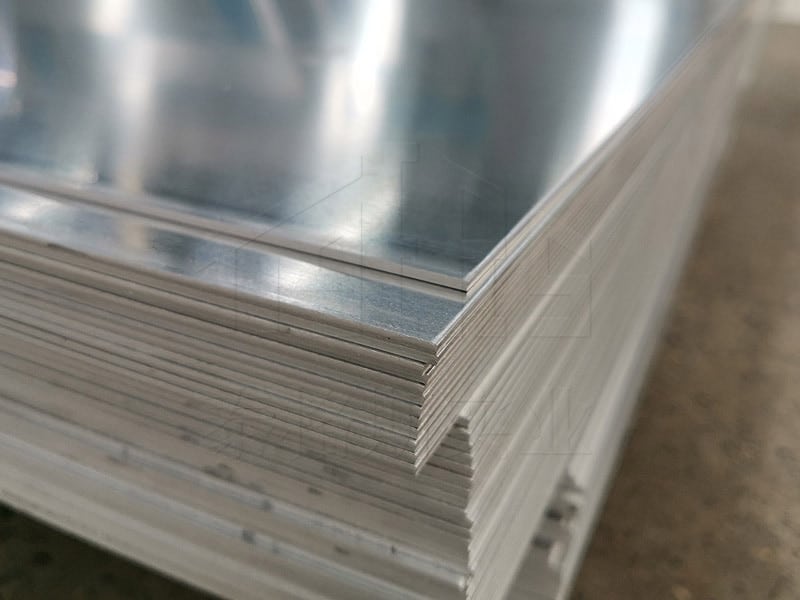

6082 aluminum sheet

6082 aluminium alloy designations

6000 series aluminum alloy:

- 6061 aluminum sheet/plate

- 6083 aluminum sheet/plate

- 6005 Aluminum sheet/plate

- 6060 Aluminum sheet/plate

- 6101 Aluminum sheet/plate

- 6005A Aluminum sheet/plate

3mm 6082 aluminum sheet

Specification of 6082 aluminum sheet

- Alloy: 6082

- Temper: O, T4, T451, T42, T6,T651,T62, T61,T6151

- Stretching capacity: 300000m² supposed width is 2000mm, then the maximum thickness is 150mm.

- Thickness: 0.3mm–600mm

- With: 20mm–3000mm

- Length: 1000mm–12000mm

- Surface: Mill finish, Bright finish, paper interleaved, one side film, both sides film.

6082 aluminum sheet/plate chemical composition (For Reference)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | Others | Aluminium min. |

|

| Each | Total | |||||||||||||

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.25 | – | 0.2 | 0.1 | – | – | 0.05 | 0.15 | Remainder |

Physical properties of 6082 aluminum sheet

TEMPER TYPES

| TEMPERS |

| O |

| T4/T451 |

| T42 |

| T6/T651/T62 |

| T61/T6151 |

The most common tempers for 6082 aluminium are :

- T6 – Solution heat treated and artificially aged .

- O – Soft .

- T4 – Solution heat treated and naturaly aged to a substantially stable condition .

- T651 – Solution heat treated, stress relieved by stretching then artificially aged .

Strength

Machinability

Forming

Corrosion resistance

Welding

6082 Aluminium sheet mechanical properties

- Mechanical Properties of 6082 Aluminum Sheet:

- Tensile strength σb (MPa): ≥ 205

- Conditional yield strength σ0.2 (MPa): ≥110

- Elongation δ10 (%): ≥14

- Sample size: all thickness

- Homogenization temperature: 555-565℃ holding time: 3 hours, cooling rate ≥ 200 ℃/h

| TEMPERS | STRENGTH (METRIC/IMPERIAL) | BRINELL HARDNESS | ELONGATION | THICKNESS | |

| Ultimate Tensile | Yield Strength | ||||

| O | 40 | 14% | 1.5 – 3mm | ||

| T4/T451 | 58 | 12% | 1.5 – 3mm | ||

| T42 | 57 | 13% | 1.5 – 3mm | ||

| T6/T651/T62 | 94 | 8% | 1.5 – 3mm | ||

| T61/T6151 | 82 | 10% | 1.5 – 3mm |

- F – As fabricated.

- T5 – Cooled from an elevated temperature shaping process and artificially aged. Applies to products that are not cold worked after cooling.

- T5511 – Cooled from an elevated temperature shaping process, stress relieved by stretching and artificially aged.

- T6 – Solution heat treated and artificially aged.

- O – Soft , Annealed. This is the lowest strength, highest ductility temper.

- T4 – Solution heat treated and naturally aged to a substantially stable condition. Applies to products that are not cold worked after solution heat-treatment.

- T6511 – Solution heat treated, stress relieved by stretching, and artificially aged.

6082 aluminum sheet advantage

- 6082 aluminum sheet has good formability, weldability, machinability and corrosion resistance;

- 6082 Aluminum Sheet with moderate strength, after the annealing can still maintain a good operability;

- good anode reaction performance, the most commonly used anode reaction methods include the removal of impurities and dyeing, coating and so on;

- 6082 aluminum sheet -0 and T4 state for bending and forming the occasion;

Usages of 6082 Aluminum Material Sheet

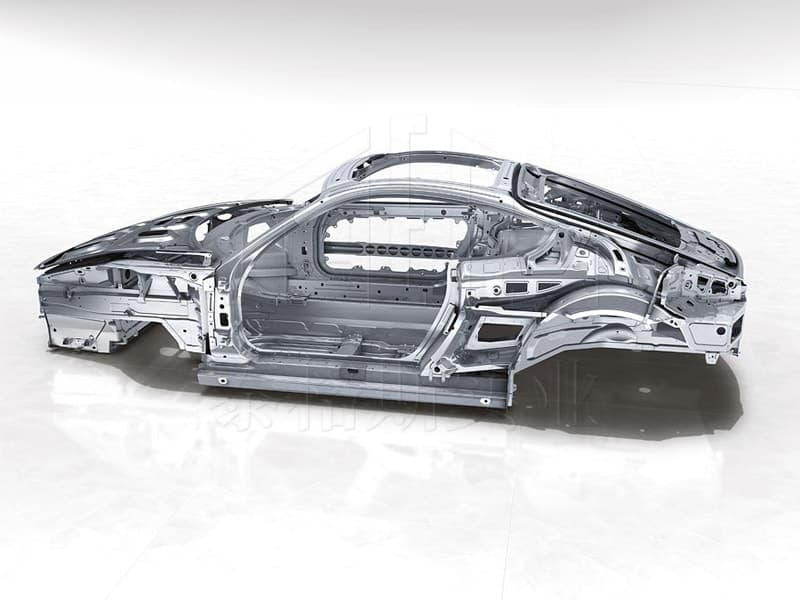

auto shell made of aluminum sheet

Applications

6082 is typically used in:

- Highly stressed applications

- Trusses

- Bridges

- Cranes

- Transport applications

- Ore skips

- Beer barrels

- Milk churns

More 6082 alloy applications:

Aviation fixtures, trucks, towers, ships, pipelines and other construction applications where strength, weldability and corrosion resistance are required. Such as: aircraft parts, camera lenses, couplers, marine accessories and hardware, electronic accessories and connectors, decorative or various hardware, hinge heads, magnetic heads, brake pistons, hydraulic pistons, electrical accessories, valves and valve parts.

Standard of 6082 aluminum sheet/plate/coil

- EN 485-2

- EN 573-3

- EN 754-2

- EN 755-2

- ISO 6361

Packing Detail of 6082 Aluminum Sheet:

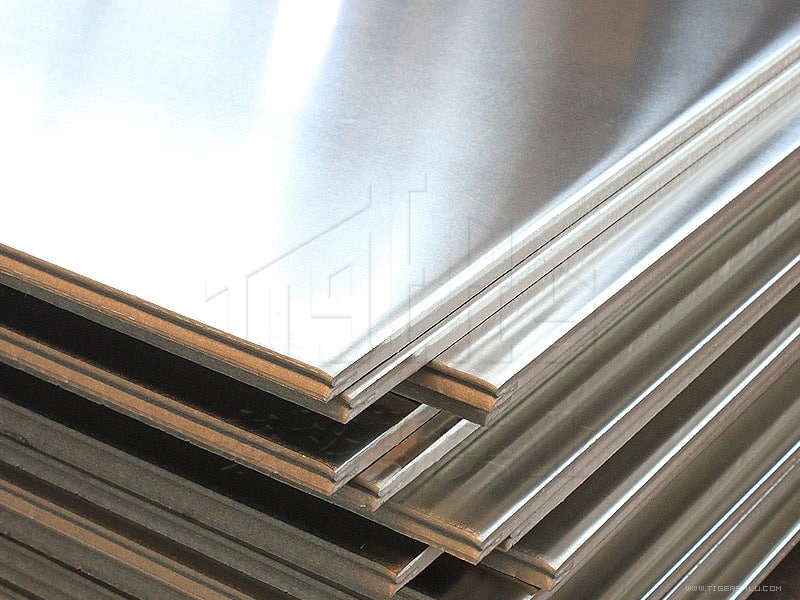

cutting edge without burrs of 6082 aluminum sheet

Why Choose Tigers aluminum as Your Source for 6082 Aluminium Sheets?

- More Than 12 Decades of Experience in Manufacture, Stock & Supply of 6082 Aluminium Sheets

- Best Prices For Alloy 6082 Aluminium Sheets – Supplied Worldwide with Shortest Delivery Time

- Exporting ASTM, EN Standard Compliant Aluminium 6082 Sheets is Our Specialty

- We Can Handle the Logistics for You – We can offer FOB, CIF Delivery to Any Port

- Documents We Provide Include – Certificate of Origin, Invoice & PL Attested by Chamber of Commerce, Test Certificates as per EN 10204 3.1, Other Testing Reports, as may be Required by Our Customers.

Features of 6082 aluminum plate sheet

- Good formability, solderability and brazeability.

- It has medium strength and good machinability.

- Good usability and excellent interface characteristics.

- Easy to process, good anode reaction performance and easy coating.

- Good corrosion resistance and oxidation resistance.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.