The main alloying addition of 3004 aluminum sheet alloy is manganese. 3004 alloy has moderate strength, good workability, and good corrosion resistance. It is commonly rolled and extruded, but typically not forged, not used in casting.

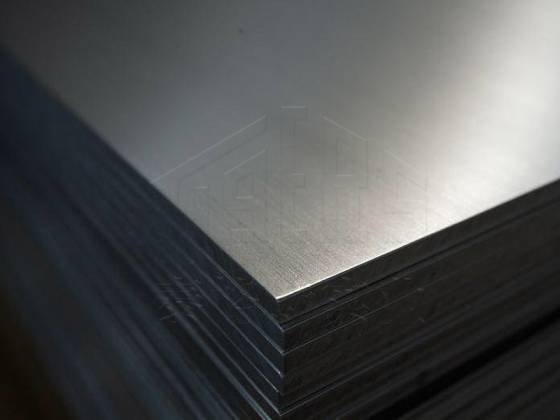

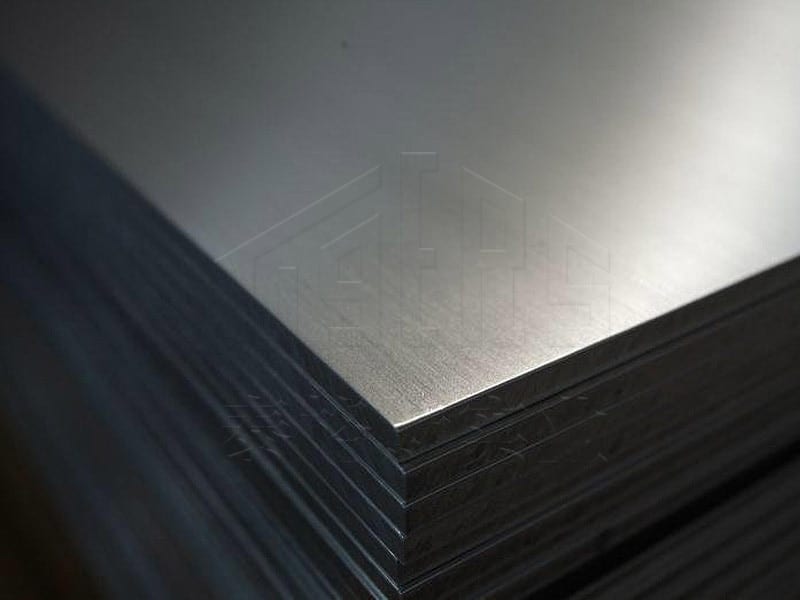

3004 aluminum sheet plate

3004 aluminium alloy is an alloy in the aluminium-manganese family (3000 or 3xxx series), is an alloy plate commonly used in 3000 series aluminum plates. Other alloys in this series include the following:

- 3003 aluminum sheet

- 3004 aluminum sheet

- 3005 aluminum sheet

- 3104 Aluminum Sheet

- 3105 aluminum sheet

- 3A21 Aluminum Sheet

3004 aluminum sheet/plate chemical composition (for reference)

Chemical Composition conforms to Chinese, American and European standard specification

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each |

Others: Total |

Al: Min. |

| 3004 | 0.30 | 0.70 | 0.25 | 1.0~1.5 | 0.8~1.3 | – | 0.25 | – | 0.05 | 0.15 | remainder |

Aluminium / Aluminum 3004 alloy is an alloy containing manganese and magnesium.3004 aluminum metal alloy is similar to 3003 except for the addition of approximately 1% magnesium.

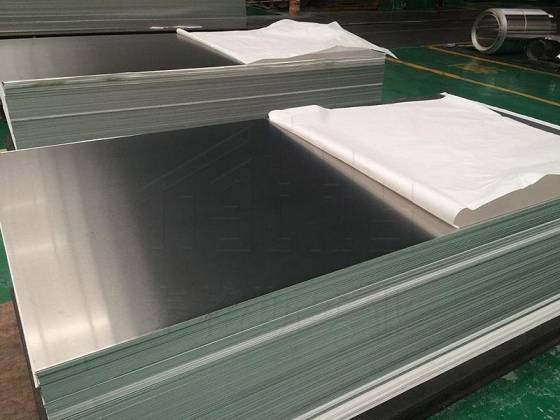

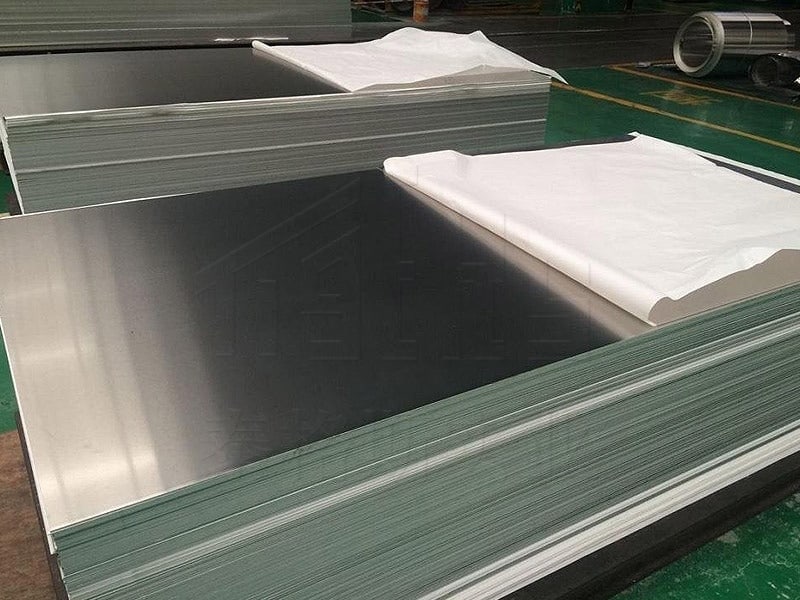

aluminum sheet interleaved with paper

Physical properties of 3004 aluminum material alloy

It can be cold worked (but not, unlike some other types of aluminium alloys, heat treated) to produce tempers with a higher strength but a lower ductility.

Data Sheet

| Alloy | Temper | Thickness (mm) |

Width (mm) |

Length (mm) |

Typical products |

| 3004 aluminum sheet | F, H112, O, H111,H12, H22, H32, H14, H24, H34, H16, H26, H18, H19, H28, H38 | 0.2-500mm | 100-2650mm | 500-16000 | Heat sink materials such as liquid crystal back |

| Principal Design Features | This is an alloy of aluminum with magnesium and manganese. It is strengthened (hardened) by cold work only as it does not respond to heat treatment, other than annealing. |

| Applications | Commonly used in the manufacture of storage tanks. Is commonly used in sheet metal work. |

| Machinability | The machinability of this alloy is considered to be excellent, especially in the hard temper. As is typical of the aluminum alloys an oil lubricant should be used for machining, although light cuts may be done dry. |

| Forming | AL 3004 is easily formed by either cold or hot working with conventional tooling. |

| Welding | The alloy is weldable by the standard methods. Best results are obtained by use of TIG or MIG welding with the same alloy as filler rod. |

| Heat Treatment | Heat treatment has no effect upon this alloy. It may be annealed after cold working however. See “Annealing”. |

| Forging | Forging may be accomplished in the range of 950 to 700 F. |

| Hot Working | AL 3004 can be hot worked at temperatures of 900 to 500 F. |

| Cold Working | Cold working capability of this alloy is good. it can readily be cold worked up to a 75% reduction of area by conventional methods. Working beyond the 75% reduction requires an intermediate anneal. |

| Annealing | Anneal at 650 F and air cool. |

| Aging | Not applicable to this alloy. |

| Tempering | Not applicable. |

| Hardening/hardness | Cold working is the only means of producing the harder (H) tempers of this alloy. |

| Other Physical Props | Electrical conductivity 39% of copper. |

| Other Mechanical Props | Shear strength for O temper is 16 ksi. H32 temper, 17 ksi and for H38 temper 21 ksi. |

| Density (lb / cu. in.) | 0.098 |

| Specific Gravity | 2.72 |

| Melting Point (Deg F) | 1170 |

| Modulus of Elasticity Tension | 10 |

| Modulus of Elasticity Torsion | 3.8 |

Advantages of 3004 aluminum metal:

It has higher strength than 3003 aluminum sheet.It is commonly rolled and extruded, but typically not forged.

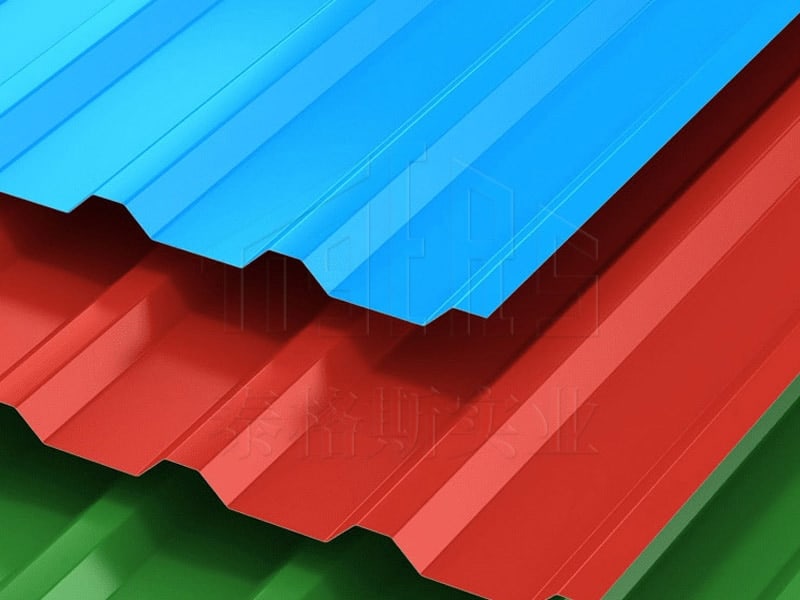

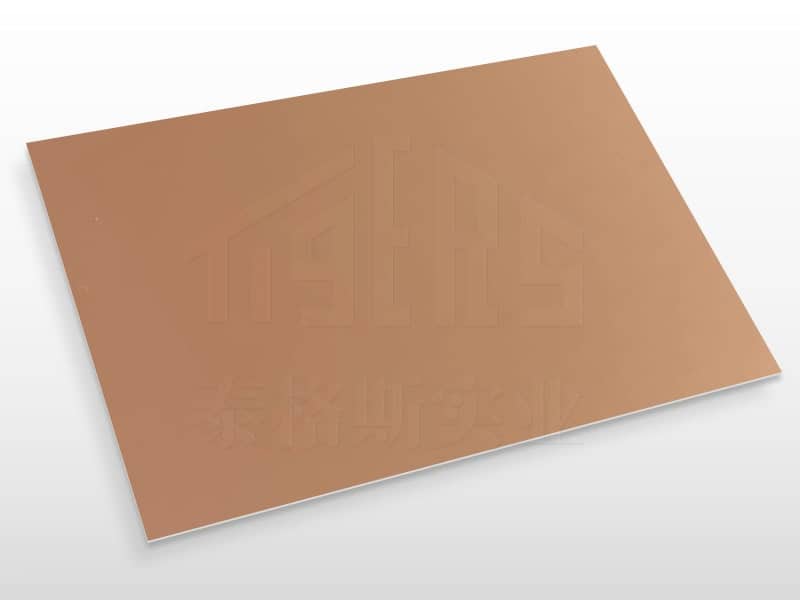

3004 Anodized aluminum sheet plate with color

The chemical makeup of 3004 is very similar to 3003. The addition of Magnesium gives it strengths approaching 5052 along with great corrosion resistance and good formability. These properties make 3004 a good candidate for storage tanks, pressure vessels and cookware.

3004 aluminum sheet properties are characterized by good formability, dissolves resistance, corrosion resistance, etc., It usually used to produce some components which request much higher strength than 3003.

- High Plasticity. 3004 aluminum sheet has high plasticity in annealing state, good plasticity in semi-cold hardening and low plasticity in cold hardening.

- Finish Well. It can adapt to the maximum speed that most machine tools can achieve so as to milling, boring, planing and other mechanical processing. In addition,3004 aluminum sheet has good weldability but poor machinability.

- Slightly Higher Intensity. With the addition of the alloy component Mn, while maintaining the excellent workability and corrosion resistance of pure aluminum, the strength of the 3004 aluminum sheet is slightly increased, higher than that of the 3003 aluminum sheet, and 10% higher than that of the 1100 series.

- Good Anodic Oxidation. The anodic oxidation surface treatment effect of 3004 aluminum sheet is amazing, which is a good choice for color coated aluminum substrate.The surface of the 3004 aluminum sheet after anodized has enhanced corrosion resistance and can also present colorful colors.

What is 3004 Aluminum Material Sheet used for?

The alloy 3004 is also used in the making of beverage cans. It was developed to satisfy the need for thinner gauges in can-stock, and thereby to some extent replaced its predecessor 3003 alloy in the making of beverage cans. Can-stock can be made thinner due to the addition of 1% magnesium, which contributes in solid solution strengthening.

aluminum can

3004 Al-Mn-Mg Alloy roofing sheet

Aluminum, magnesium and manganese roof sheet, as its name implies, are made of alloys of aluminium, magnesium and manganese. Aluminum is light in weight and not easy to oxidize. Magnesium is soft in nature. Manganese metal has good corrosion resistance and toughness. The aluminum roofing sheet made of the three alloys have the characteristics of light weight, corrosion resistance and strong plasticity.

Roof aluminium sheet are Aluminum-Magnesium-Manganese alloy 3003 or 3004 special used for metal roofing, the thickness is 0.5mm-1.2mm. Usually, the 3003 and 3004 aluminium roofing sheet are coated with PE and PVDF coating to have beautiful appearance and long service life. After color coated, the aluminium roofing sheet system can withstand corrosion and sunshine, and the active life can be as long as 25 years without fade.

The 3003 aluminum alloy is harder, while the 3004 aluminium alloy is softer, and the price of 3004 aluminum alloy is more expensive.

Standard & Specifications of 3004 aluminum sheet/plate/coil

The following specifications cover Aluminum 3004

- ASTM B 209: Standard Specification for Aluminium and Aluminium-Alloy Sheet and Plate

- ASTM B 221: Standard Specification for Aluminium and Aluminium-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

- ASTM B 547: Standard Specification for Aluminium and Aluminium-Alloy Formed and Arc-Welded Round Tube

- ISO 6361: Wrought Aluminium and Aluminium Alloy Sheets, Strips and Plates

3004 aluminum sheet cutting

Alternate designations

- 3.0526

- A93004.

wikipedia for 3004 aluminum alloy

The different between 3003 aluminum plate and 3004 aluminum plate

Why choose Tigers’s 3004 aluminum?

- Best Prices For Alloy 3004 Aluminium Plates – Supplied Worldwide with Shortest Delivery Time.

- Exporting ASTM, EN Standard Compliant Aluminium 3004 Plate is Our Specialty.

- We are a manufacturer and stockist of 3004 aluminum sheet, which can be cut to the size you need and shipped quickly via overseas warehouses and international logistics, giving you the “near me” experience and peace of mind with after-sales service.

- We Can Handle the Logistics for You – We can offer Exworks, FOB, CFR, CIF Delivery to Any Port.

- Documents We Provide Include – Certificate of Origin, Invoice & PL Attested by Chamber of Commerce, Test Certificates , Other Testing Reports, as may be Required by Our Customers.

Where can i buy 4×8 sheets of aluminum?

Tigers is a leading manufacturer and supplier of aluminium 3004 alloy plates in compliance with ASTM B209, EN 573 and EN 485 standards.

We with large stocks of 3004 aluminium sheets and plates and cut to size aluminium plate profiles.We specialise in the supply of aluminium plate cut circles, strips and blanks.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.