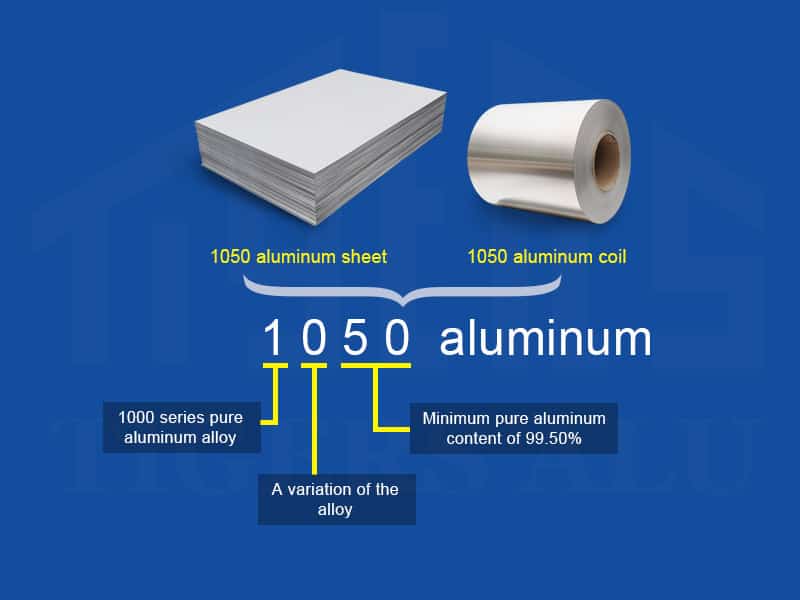

What is 1050 Aluminium alloy?

1050 aluminum sheet belongs to 1000 series aluminum alloy metal. It belongs to a commercially pure wrought family with a purity of 99.5% Al.

1050 aluminum alloy grade

In addition to the component Al, 0.4% Fe is added, so 1050 aluminum alloy also has high conductivity.

1000 series aluminium group offers the best correction tensile to any alloy group, so does the 1050 aluminium sheet. It has a high tensile strength and can be formed into many shapes to meet the needs of various industries.

1050 aluminum sheet has excellent corrosion resistance, high ductility and high reflectivity. These excellent properties determine its position in industrial processing and decoration industries, and have a high usage rate in these industries.

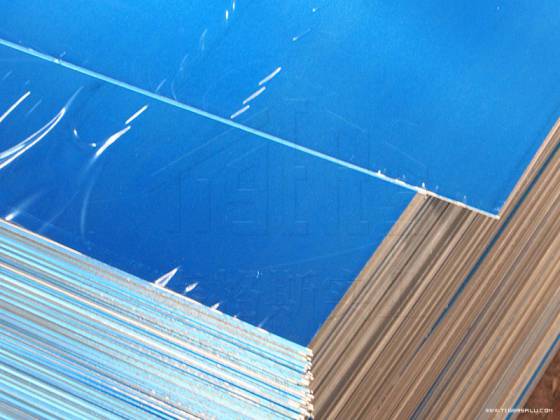

1050 aluminum sheet with blue films

1050 aluminium Alloy Designations

Aluminium alloy 1050 also corresponds to the following designations:

- AA1050A

- S1B

- A91050

1050 aluminum sheet/plate chemical composition (For Reference)

Chemical Composition conforms to Chinese, American, and European standard specification

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: each other |

Others: total |

Al: Min. |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | – | 0.05 | 0.03 | 0.03 | – | 99.50 |

| 1050A | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | – | 0.07 | 0.05 | 0.03 | – | 99.50 |

Physical properties of 1050 aluminum sheet

Tigers have 12 years of 1050 aluminum sheet and plate production experience and can produce and supply high-quality 1050 aluminum sheets. In addition, different temper can be provided, such as O (annealed), H12, H14, H18, H24, and so on.

1050 aluminum coil sheet which has better correction resistance than other alloy series. Aluminium alloy 1050 is a popular grade of aluminium for general sheet metal work where moderate strength is required.

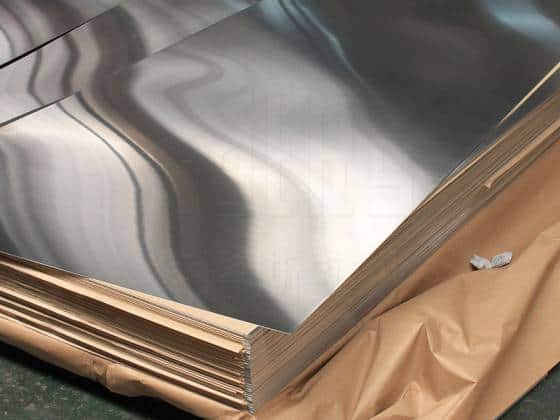

1050 aluminum sheet interleaved with paper

1050 aluminum sheet is a non-heat treatment alloy, which is enhanced by cold working and has excellent cold workability, solderability, and weldability.

Aluminium alloy 1050 is known for its excellent corrosion resistance, high ductility, excellent electrical and thermal conductivity, and highly reflective finish, but the strength of 1050 aluminum alloy is low, so 1050 aluminum alloy is well suitable for chemical and electrolytic brightening but not in casting.

| Physical Property | Value |

| Density | 2.71 g/cm³ |

| Melting Point | 643°C (1190°F) |

| Thermal Expansion | 24 x10^-6 /K |

| Modulus of Elasticity | 71 GPa |

| Tensile strength | 55 MPa (8000 psi) |

| Yield strength | 20 MPa (2900 psi) |

| Elongation | 35% |

| Thermal Conductivity | 222 W/m.K |

| Electrical Resistivity | 0.0282 x10^-6 Ω .m |

The important point is that the surface of the 1050 aluminum sheet can be anodized. In addition, it has medium strength and excellent processing technology making 1050 aluminum sheets have a wider range of applications.

1050 aluminum sheet is easy to fabricate using a variety of techniques, including:

- Cutting

- Bending

- Forming

- Welding

- Brazing

- Soldering

1050 aluminum sheet advantage

- commercially pure aluminum

- non heat-treatable

- soft and ductile

- excellent cold workability

- excellent corrosion resistance

- easily welded by MIG or TIG processes

- excellent brazability and solderabilit

- well-suited to chemical and electrolytic brightening

- very good anodizing qualities

- has a highly reflective finish

1050 aluminum sheet packing and stock

1050 Aluminium sheet mechanical properties

| Process | Rating |

| Workability – Cold | Excellent |

| Machinability | Poor |

| Weldability – Gas | Excellent |

| Weldability – Arc | Excellent |

| Weldability – Resistance | Excellent |

| Brazability | Excellent |

| Solderability | Excellent |

Temper Of 1050 Aluminum Sheet

1050 alloy aluminum sheet exhibits different physical properties in different annealed states. Common annealed states are O, H111, H12, H14, H16, H18, H22, H24, etc..

The most common tempering state of 1050 aluminum sheet is H14 – rolled semi-hard work-hardened, rolled without annealing.

| Alloy Temper | Specified | Tensile strength | Yield strength | Elongation | ||||||||

| Thickness(mm) | (MPa) | (MPa) | (%) | |||||||||

| 1050-O/ 1050-H111 | 0.2-0.5mm | 65-95 | Min20 | Min20 | ||||||||

| 0.5-1.5mm | Min22 | |||||||||||

| 1.5-3.0mm | Min26 | |||||||||||

| 3.0-6.0mm | Min29 | |||||||||||

| 6.0-12.5mm | Min35 | |||||||||||

| 12.5-80.0mm | ||||||||||||

| 1050-H112 | 6.0-12.5mm | Min75 | Min30 | Min20 | ||||||||

| 12.5-80.0mm | Min70 | Min25 | ||||||||||

| 1050-H12 | 0.2-0.5mm | 85-125 | Min65 | Min2 | ||||||||

| 0.5-1.5mm | Min4 | |||||||||||

| 1.5-3.0mm | Min5 | |||||||||||

| 3.0-6.0mm | Min7 | |||||||||||

| 6.0-12.5mm | Min9 | |||||||||||

| 12.5-40.0mm | ||||||||||||

| 1050-H14 | 0.2-1.5mm | 105-145 | Min85 | Min2 | ||||||||

| 1.5-3.0mm | Min4 | |||||||||||

| 3.0-6.0mm | Min5 | |||||||||||

| 6.0-12.5mm | Min6 | |||||||||||

| 12.5-25mm | ||||||||||||

| 1050-H16 | 0.2-0.5mm | 120-160 | Min100 | Min1 | ||||||||

| 0.5-1.5mm | Min2 | |||||||||||

| 1.5-4.0mm | Min3 | |||||||||||

| 1050-H18 | 0.2-0.5mm | Min135 | Min120 | Min1 | ||||||||

| 0.5-1.5mm | Min140 | Min2 | ||||||||||

| 1.5-3.0mm | Min2 | |||||||||||

| 1050-H19 | 0.2-0.5mm | Min155 | Min140 | Min1 | ||||||||

| 0.5-1.5mm | Min150 | Min130 | ||||||||||

| 1.5-3.0mm | ||||||||||||

| 1050-H22 | 0.2-0.5mm | 85-125 | Min55 | Min4 | ||||||||

| 0.5-1.5mm | Min5 | |||||||||||

| 1.5-3.0mm | Min6 | |||||||||||

| 3.0-6.0mm | Min11 | |||||||||||

| 6.0-12.5mm | Min12 | |||||||||||

| 1050-H24 | 0.2-0.5mm | 105-145 | Min75 | Min3 | ||||||||

| 0.5-1.5mm | Min4 | |||||||||||

| 1.5-3.0mm | Min5 | |||||||||||

| 3.0-6.0mm | Min8 | |||||||||||

| 6.0-12.5mm | ||||||||||||

| 1050-H26 | 0.2-0.5mm | 120-160 | Min90 | Min2 | ||||||||

| 0.5-1.5mm | Min3 | |||||||||||

| 1.5-4.0mm | Min4 | |||||||||||

| 1050-H28 | 0.2-0.5mm | Min140 | Min110 | Min2 | ||||||||

| 0.5-1.5mm | ||||||||||||

| 1.5-3.0mm | Min3 | |||||||||||

The brand of aluminum alloy from which the Aluminum 1050 sheet is made determines its properties.

The excellent properties of 1050 aluminum alloy sheet are the basis for its wide use in the following sectors.

1050A aluminum alloy (1050 alloy) is available in sheet, plate, strip, bar, wire, drawn tube, welding wire, forged material and rivet material.

However, 1050 aluminum plate has low mechanical strength compared to more strongly bonded metals.

What is 1050 Aluminium alloy used for?

1050 alloy has exquisite corrosion resistance, excessive ductility, moderate strength, and a highly reflective finish. This grade of alloy is most appropriate for use as food industrial containers, architectural flashings, cable sheathings, lamp reflectors, manufacturing of food cans, beverage cans, automotive parts, and other products and chemical method plant equipment.

1050A aluminum sheet is commonly used in some places that require high corrosion resistance and formability but not high strength. 1050 aluminum sheet is also industrial aluminum. For example, A typical application is the manufacture of chemical industry containers.

In addition,1050 aluminum alloy is used for lithium battery soft connection, pole material, explosion-proof valve, PS board base, heat sink, signage, lamp, reflector, etc.

- Chemical process plant equipment

- Food industry containers

- Pyrotechnic powder

- Architectural flashings

- Lamp reflectors

- Cable sheathing

Aluminum 1050 alloy is also sometimes used for the manufacture of heat sinks, since it has a higher thermal conductivity than other alloys.

The other type of 1000 series aluminum sheet

- 1050 Aluminum Coil Sheet

- 1060 Pure Aluminum Coil Sheet Plate

- 1070 Pure Aluminum Sheet Plate

- 1100 Aluminum Sheet

- 1200 Aluminum Sheet Plate

Multi-product made of 1050 aluminum alloy sheet metal

Aluminium Alloy 1050 (1050 A) is available in Plate, Sheet, Strip, Bar, Wire, Drawn Tube, Welding Wire, Forging Stock, and Rivet Stock.

traffic sign

Welding of 1050 aluminum sheet

When welding 1050 to itself or an alloy from the same subgroup the recommended filler wire is 1100. For welding to alloys 5083 and 5086 or alloys from the 7XXX series, the recommended wire is 5356. For other alloys use 4043 filler wire.

More information about 1050 aluminium

1050 aluminium alloy Wikipedia

Specification of 1050 aluminum coil sheet

| Dimension | Range |

| Thickness | 0.5 ~ 6.0mm for sheet,max 500mm |

| Width | 600 ~ 2,200mm |

| Length | 2,000 ~ 10,000mm |

- – Standard Width and Length: 4〃 x 8〃, 4“ x 4“ , 4 in. x 10 in. aluminum sheet, 5 x 10 aluminum sheet, 48‘ x 96’ aluminum sheet, 1219 * 2438mm, 1220mm x 2440mm aluminum sheet, 1000mm x 2000mm aluminum sheet, 1250mm x 2500mm, 1219x2438mm, 1524x3048mm, 1500mm x 3000mm aluminum sheet.

- – Surface Finish: Mill finish (unless otherwise specified), Color Coated, or Stucco Embossed

- – Surface Protection: Paper interleaved, PE/PVC filming (if specified)

- – Minimum Order Quantity: 3MT

Standard of 1050 aluminum sheet/plate/coil

- ASTM B209 – This specification covers aluminum and aluminum alloy flat sheets, coiled sheets, and plates in various alloys.

- BS EN 573 – This specification covers aluminium and aluminium alloys – Chemical composition and form of products.

- BS EN 485 – This specification sets out the mechanical properties of wrought aluminium and wrought aluminium alloy sheet, strip, and plate for general engineering applications.

1050 aluminium alloy sheet can be used as anodized aluminum sheet, deep drawing aluminum, good mechanical properties, and widely used.

Packing of 1050 Aluminum Sheet

1050 aluminum sheet is packaged in a way that meets export standards.

We can cover plastic film and kraft paper interlayer according to customer’s needs. On the outside, wooden boxes or wooden pallets are usually used to protect the products from damage during transportation.

packing aluminum sheets

How to Choose a Quality & Cost Effective 1050 Aluminum Sheet Supplier?

A quality supplier is a business that has a good reputation, honors its commitments, and meets the needs of its customers. A quality supplier is also one that provides excellent customer service and maintains an ethical business culture.

There are many qualities to look for in a quality aluminum sheet supplier.

- Firstly, they should have a good reputation. They should be known for being fair and honest with their customers as well as being reliable and trustworthy.

- Secondly, they should have a variety of products to choose from because not everyone needs the same thing or wants the same thing so it’s important to have options.

- Thirdly, they should be cost-effective because you want the best value for your money without sacrificing quality or service so you can save money in other ways such as marketing costs or by cutting back on staff hours.

Tigers Aluminum is one of the leading suppliers and manufacturers of 1050 aluminum sheets in China, specializing in the production of 1050 aluminum sheets and other aluminum products. Our product line includes high-quality aluminum 1050 h18 sheet, aluminum alloy 1050 h24 sheet, and aluminum alloy 1050 O coil for sale.

As a trusted supplier, we are committed to delivering superior products and services to meet the needs of our customers. Contact us today to learn more about our high-quality aluminum products and how they can benefit your business.

Aluminum 1050 vs aluminium 5052

Aluminum 1050 is a low-cost aluminum alloy. It has good corrosion resistance and good formability. The product can be used in the production of general-purpose building materials, household appliances, machinery parts, and other products.

Aluminum 5052 is an alloy of aluminum with copper and magnesium. It has better corrosion resistance than 1050 aluminum. The product can be used in the production of aircraft, rail cars, ships, containers for corrosive liquids or gases like sulfuric acid or chlorine gas.

More about 1050 aluminum sheet plate

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.