Tigers Industry supplies mill finished aluminium sheets and coils of alloy 1050, 1060, 1070, 1100, the aluminium alloys are widely used for industrial purpose and chemical equipment.

1000 series aluminum sheet, aluminum sheet metal provided by Tigers aluminum includes 1050 aluminum sheet, 1060 aluminum sheet, 1070 aluminum sheet, 1100 aluminum sheet etc. The 1050, 1060, 1070 and 1100 series are representative series.

aa1050 h14 aluminium sheet

1000 series aluminum sheet, also called pure aluminum sheet, has the highest aluminum content among all the series produced by Tigers,Its aluminum content can be more than 99.00%.

The last two numbers in the serial number are used to determine the lowest aluminum content of this series. For example, in the 1050 series, the last two numbers are 50 and according to the corresponding international standard, the aluminum content has to reach 99.5% or more. In GB/T3880-2006, the technical standard of aluminum alloy in China, 1050 series also means the aluminum content has to reach 99.5%. Similarly, the aluminum content of 1060 series aluminum sheet has to reach 99.6% or more.

As no other techniques are involved in the production, the production procedure is single and the price is cheap. It is a commonly used aluminum sheet in conventional industries.

1000 aluminum sheet specification

The common sizes of 1000 series aluminum sheets are:

4〃 x 8〃 aluminum sheet, 4“ x 4” aluminum sheet, 4 in. x 10 in. aluminum sheet, 5 x 10 aluminum sheet, 48‘ x 96’ aluminum sheet, 1219 * 2438mm aluminum sheet, 1220 x 2440mm aluminum sheet, 1000mm x 2000mm aluminum sheet, 1250 x 2500mm aluminum sheet, 1500 x 3000mm aluminum sheet.

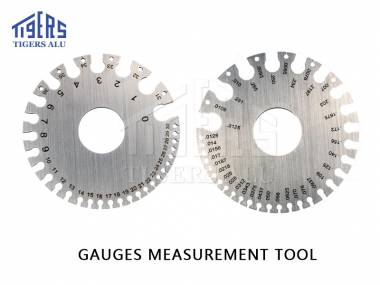

The common thicknesses are:

0.5 mm aluminium sheet, 1.0 mm aluminium sheet, 1.5 mm aluminium sheet, 2mm aluminium sheet, 2.5mm aluminium sheet, 3mm aluminium sheet, 5mm aluminium sheet, 6mm aluminium sheet, max thickness 500mm.

1000 series aluminum sheet Alloy Designation (For Reference)

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 1xxx Series | 1050 | – | – |

| 1050A | – | EN AW-1050A | |

| 1060 | 1060 | – | |

| 1100 | 1100 | – |

1050 H14 aluminium sheets widely used for aluminium curtain wall panel

1050 aluminum sheet belongs to commercially pure wrought family with a purity of 99.5% Al. It also belongs to 1000 series aluminum alloy, which has better correction resistance than other alloy series. In the 1050 aluminum sheet, in addition to the component Al, 0.4% Fe is added, so 1050 aluminum alloy also has high conductivity. In general, 1050 aluminum sheet properties exhibit high plasticity, strong corrosion resistance, excellent electrical and thermal conductivity, but the strength of 1050 aluminum alloy is low.

Chemical Composition for 1050 aluminum sheet

Chemical Composition conforms to Chinese, American and European standard specificationmingt

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each |

Others: Total |

Al: Min. |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | – | 0.05 | 0.03 | 0.03 | – | 99.50 |

| 1050A | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | – | 0.07 | 0.05 | 0.03 | – | 99.50 |

- Features of 1050 aluminium alloy:

aluminium plate 1050 contains more than 99.5% aluminium and is also called pure aluminium, with the existence of 0.4% Fe, 1050 aluminium alloy sheet has high conductivity, and with the excellent work-ability, solder-ability and weld-ability, it is widely use for aluminium curtain wall system, and the thickness ranges from 2.0-4.0 mm for this purpose. - aluminium curtain wall panel

The most common temper of 1050 aluminium sheet is O (annealed), H12, H14, H18 and so on. - Properties of 1050 aluminium alloy:

In addition, 1050 aluminium alloy with the high plasticity, strong corrosion resistance, high conductivity, it is widely used for industrial manufacturing.

aluminium curtain wall panel

1060 aluminium coil strip for transformer with excellent conductivity

Chemical Composition for 1060 aluminum sheet (For Reference)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each |

Others: Total |

Al: Min. |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | – | 0.05 | 0.03 | 0.03 | – | 99.60 |

Features of 1060 aluminium alloy:

aluminium plate 1060 contains more than 99.6% aluminium and is also called pure aluminium. It belongs to a commonly used series in the aluminium plate and strip family.

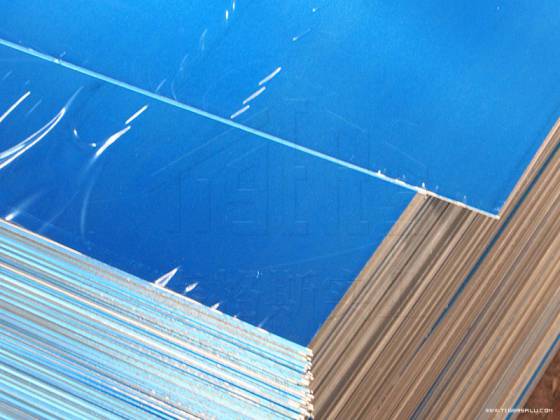

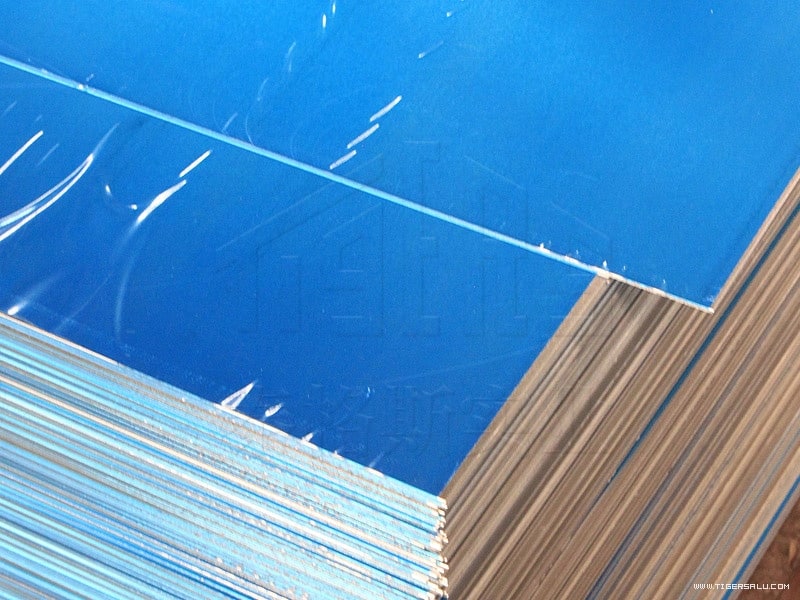

aluminum sheet with blue films

Advantages of this series of aluminium sheet:

the most commonly used series, the production process is relatively simple, the technology is relatively mature, and the price has a huge advantage over other high-grade alloy aluminium plates. With good elongation and tensile strength, it can fully meet the conventional processing requirements (stamping, stretching) and high form-ability.

Industrial pure aluminium, with high form-ability, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, heat treatment can not strengthen the machinability; it can be gas welding, hydrogen atom welding and contact welding, not easy to braze; easy to bear different kinds of pressure processing and extension, bending.

Properties of 1060 aluminium alloy:

1060 aluminium plate has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity.

- Uses of hot-rolled 1060 aluminium sheet:

flexible battery connection, bus interior decoration, auto parts, aluminium composite panels, traffic signs, lamps, wide curtain walls, bus luggage racks/floors/checkered plates, etc.; - Uses of hot-rolled 1060 medium-thick aluminium plates:

aluminium bus bars, automobile radiators, new energy vehicle charging piles, molds, etc.; - Uses of 1060 aluminium foil coils:

aluminium foil gaskets, food packaging, electronic labels, aluminium foil for automobile heat shields, battery foil, battery flexible connections, battery lugs, battery explosion-proof valves, etc.; - Uses of hot-rolled 1060-O state aluminium:

automotive heat shields, electronic tags, flexible battery connections, battery lugs, aluminium foil for battery explosion-proof valves, etc.;

traffic sign

1060 aluminium sheets for traffic sign and nameplate with different shapes (circle, triangle, square, rectangle, hexagon and etc.)

Because of the outstanding performance of ductility, work-ability, easy to cut, and easy stamping and forming, and the characteristic of corrosion and weather resistance, 1000 series or 3000 series aluminium sheets are common alloys to make traffic signs and name plate, the most widely used alloys are 1060 and 3004 aluminium sheet, 5000 series aluminium alloys are also widely used for highway signs. 1060, 3004 O, 5052 H38 aluminium sheets for traffic sign and nameplate with different shapes (circle, triangle, square, rectangle, hexagon and etc., the thickness range from 1.0mm to 3.0 mm.

| Dimension | Range |

| Thickness | 0.5 ~ 6.0mm for sheet |

| Width | 600 ~ 2,200mm |

| Length | 2,000 ~ 10,000mm |

- Standard Width and Length: 1000x2000mm, 1250x2500mm, 1500x3000mm, 1219x2438mm, 1524x3048mm

- Surface Finish: Mill finish (unless otherwise specified), Color Coated, or Stucco Embossed

- Surface Protection: Paper interleaved, PE/PVC filming (if specified)

- Minimum Order Quantity: 3MT

1070 aluminium sheet for industrial usage

1070 aluminum sheet contains 99.7% Al, which is the alloy sheet with the highest Al content in the 1 series of industrial aluminum.Therefore, 1070 aluminum alloy has retained the excellent properties of pure aluminum itself, such as elongation processing, thermal conductivity, corrosion resistance and so on.In addition, the mechanical properties of 1070 aluminum sheet were slightly enhanced by the addition of a few alloying elements.

Similarly, as a representative alloy sheet of industrial aluminum,1070 aluminum sheet price is low, high economy, which can be widely used in bus duct, wires, vacuum tube isolation nets, cable nets, wire cores, plane ventilation system parts and decorative parts, etc.

Chemical Composition for 1070 aluminum sheet (For Reference)

Chemical Composition conforms to Chinese, American and European standard specification

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each |

Al: Min. |

| 1060 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | – | 0.04 | 0.03 | 0.03 | 99.70 |

Features of 1070 aluminium alloy:

With the contain of 99.7% aluminium, 1070 aluminium alloy is the highest Al content in the 1 series of industrial aluminium, therefore, 1070 aluminium alloy has retained the excellent properties of the pure aluminium, including elongation processing, thermal conductivity, corrosion resistance and etc.

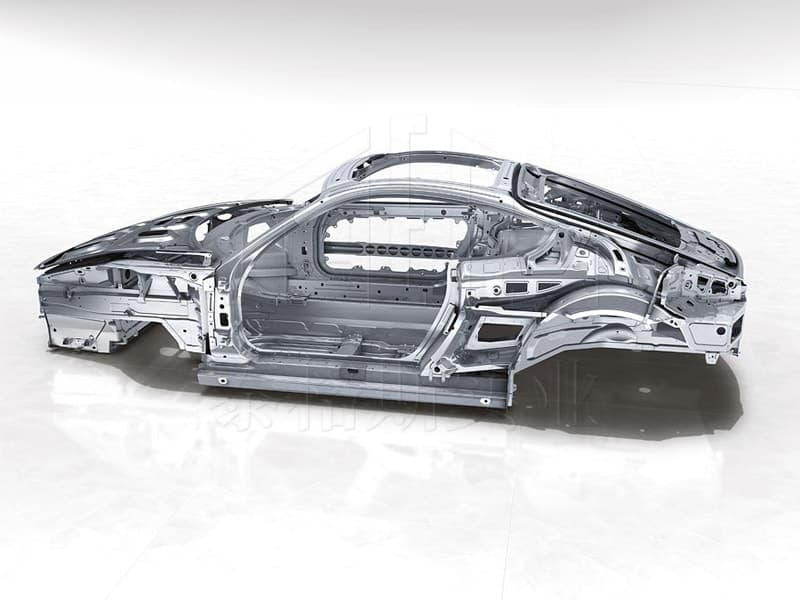

auto shell made of aluminum sheet

Application of 1070 aluminium alloy:

1070 aluminium sheet has some features such as high plasticity, anti-corrosion, electrical conductivity and good thermal conductivity, but low strength. And the machinability is not good without heat treatment. It can be used for gas welding. This specific properties of 1070 aluminum alloy can be used to produce some structures such as aluminium gasket and capacitor, electronic wire, pipe net, protective sleeve, cable net, wire core, plane ventilation system parts and decorative parts, etc.

1100 H16 Aluminium Coils for aluminium Composite Panels

1100 aluminum sheet is one of the representatives of 1 series pure aluminum sheet, which is used for industry.It is not difficult for us to find the last two Arabic digits 00 in grade 1100.In fact, this represents more than 99.00% aluminum in 1100 aluminum sheet on an international scale.The aluminum content of 99.00% makes the 1100 aluminum sheet retain the advantages of the aluminum itself to the greatest extent.For example, it has excellent ductility of pure aluminum, high corrosion resistance, excellent conductivity and thermal conductivity.

At the same time, with the addition of a small part of the alloy component Cu, the process ability and surface processing of 1100 aluminum sheet and other alloy characteristics are enhanced, which can be better used for large storage tanks, food and chemical handling and storage equipment, sheet metal products, welding assemblies, reflectors, nameplates and so on.

Features of 1100 aluminium alloy:

With the contain of 99% aluminium, 1100 aluminium sheet is industrial pure aluminium alloy, it has good forming and machining performance, high corrosion resistance but no high strength.

Application of 1100 aluminium alloy:

1100 H16 Aluminium Coils for aluminium Composite Panels for construction,with the thickness range from 0.12 mm to 0.45 mm.

Other application of 1100 aluminium sheet and coil: 0.35mm thickness 1100-H16 aluminium coil for refrigerator aluminium liners, 1100 aluminium coil is widely used for radiator, spinning, stamping parts, sheet metal processing, nameplate, fan blades, chemical instruments, transportation equipment components.

Chemical Composition for 1100 aluminum sheet (For Reference)

Chemical Composition conforms to Chinese, American and European standard specification

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each |

Others: Total |

Al: Min. |

| 1100 | 0.95 Si + Fe | 0.05~0.20 | 0.05 | – | – | 0.1 | – | 0.05 | 0.15 | 99.0 | |

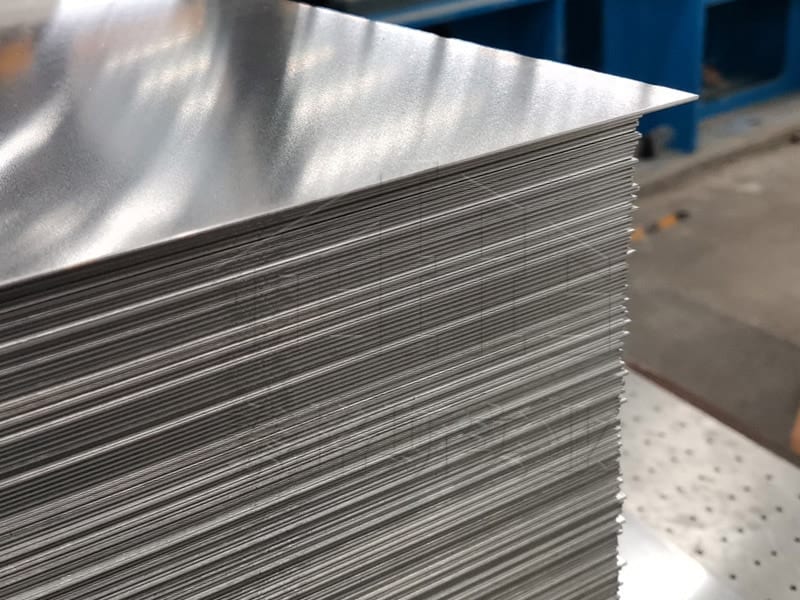

Tigers Industry supplies mill finished aluminium coils and sheets of alloy 1050, 1060, 1070, 1100, 3003, 3004, 3104, 3105, 5005, 5052, 5083, 5754, 6061, 6063, 6082, 8011, 8021, 8079 and etc. Among the above aluminium alloy, 1050, 1060, 1100 belongs to 1000 series, they are close to pure aluminium.

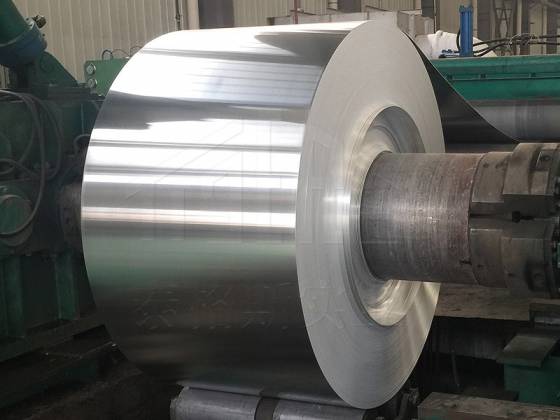

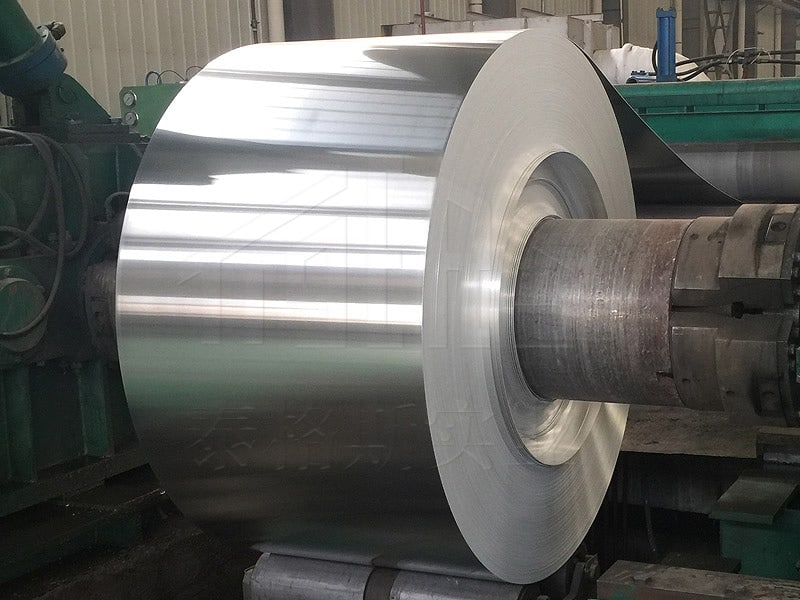

slitted aluminum coil

Application of 1000 series aluminum sheet/coil

Aluminum sheet or plate is used in various applications, including aerospace, military, transportation, etc. Aluminum sheet or plate is also used for tanks in many food industries, because some aluminum alloys become tougher at low temperatures.

| Type | Application |

| Food Packaging | Beverage can end, can tap, cap stock, etc. |

| Construction | Curtain walls, cladding, ceiling, heat insulation and venetian blind block, etc. |

| Transportation | Automobile parts, bus bodies, aviation and shipbuilding and air cargo containers, etc. |

| Electronic Appliance | Electrical appliances, telecommunication equipment, PC board drilling guide sheets, lighting and heat radiating materials, etc. |

| Consumer Goods | Parasols and umbrellas, cooking utensils, sports equipment, etc. |

| Other | Military, color coated aluminum sheet |

The width is between 20-1900mm, the thickness is between 0.2-8mm for aluminium coils, 0.2-500mm for aluminium sheets and plates. Tigers Industry provides non-standard size decoiling aluminium sheet and plate in various widths and lengths. It is suitable for curtain wall processing, traffic signs and hardware processing.

Tigers Industry also can provide filming, cutting, slitting and other processing, special specifications and materials can be customized processing, short delivery time, welcome to inquire.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.